NewsDetails

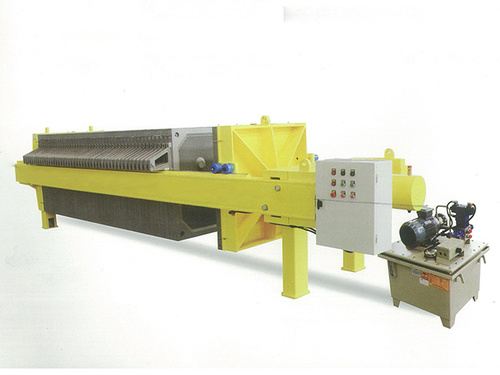

Automatic Hydraulic Filter Press for Modern Plants

author:Shuangcheng time:2025-10-24 20:59:34 Click:59

Across industries, manufacturers are constantly upgrading their processes to achieve higher output and more sustainable production. Among the most practical innovations is the Automatic Hydraulic Filter Press, a system designed for high-performance solid–liquid separation.

By combining hydraulic compression with intelligent automation, this equipment delivers clean filtrate, compact filter cakes, and consistent efficiency — making it a key asset in modern plants. Many China manufacturers now supply these presses in bulk, with flexible configurations to suit a wide range of industrial applications.

How Hydraulic Filter Press Systems Work

A Hydraulic Filter Press functions by channeling slurry into a series of filter chambers lined with durable filter cloths. Once the chambers are filled, hydraulic pistons apply controlled pressure, pushing liquid through the filter medium while retaining solid residues as dense cakes.

Automatic models feature advanced controls that handle plate shifting, cake release, and self-cleaning cycles. This level of automation not only minimizes manual labor but also improves process stability and cleanliness, ensuring smooth operation around the clock.

The results are twofold:

·Clear filtrate, often reusable in subsequent processing;

·Dry solid cakes, which are easier to handle, store, or dispose of safely.

Core Advantages of Automatic Hydraulic Operation

1. Accelerated Filtration Cycles

Automation reduces downtime between cycles and keeps the system running at optimal speed, increasing overall productivity.

2. Consistent and Repeatable Results

Each cycle is managed by a PLC or smart control unit, maintaining steady pressure and timing. This ensures consistent product quality and reliable filtration output.

3. Reduced Labor and Operational Costs

With automatic plate shifting and self-cleaning features, fewer workers are required for supervision, lowering labor expenses while improving safety.

4. Improved Safety and Control

Modern presses include automatic overload protection and pressure monitoring systems to prevent accidents and equipment damage.

5. Resource Optimization

The Hydraulic Filter Press conserves both water and energy through effective recycling of filtrate and efficient hydraulic compression, supporting eco-friendly production.

6. Custom Engineering

Manufacturers offer diverse designs tailored to specific materials — from chemical slurries to food processing waste — making this equipment adaptable to nearly any production environment.

Industrial Applications and Adaptability

Automatic Hydraulic Filter Press systems are indispensable across a wide range of industries:

·Mining and Metallurgy: Dewatering tailings and recovering valuable mineral concentrates.

·Chemical Processing: Clarifying and purifying chemical slurries and by-products.

·Food & Beverage: Filtering edible oils, fruit juices, and dairy derivatives.

·Pharmaceuticals: Ensuring purity and sterility in drug ingredient separation.

·Wastewater Treatment: Dewatering sludge efficiently, producing clean discharge water.

Their versatility, compact design, and scalability make them ideal for both small facilities and large-scale industrial complexes.

Maintenance Strategies for Reliable Performance

To keep a Hydraulic Filter Press running efficiently, regular maintenance is crucial. Here are practical steps to follow:

·Inspect hydraulic systems frequently to prevent fluid leaks or pressure loss.

·Replace worn cloths and gaskets to maintain filtration quality.

·Clean discharge paths and ensure plates remain properly aligned.

·Monitor automation systems, including sensors and control panels, to prevent malfunction.

·Flush and sanitize filter chambers regularly, especially in food or chemical applications.

Routine maintenance extends equipment lifespan, ensures smooth operation, and minimizes unplanned downtime.

Partnering with Professional China Manufacturers

Collaborating with a trusted China supplier or China manufacturer ensures access to high-quality Hydraulic Filter Press systems that meet international standards. Advantages include:

·Bulk supply to support large-scale plant installation;

·Tailored engineering for specific materials or processing capacities;

·Efficient pricing due to optimized production in China;

·Comprehensive after-sales service, including spare parts and technical guidance.

China’s hydraulic filtration industry has matured rapidly, with local manufacturers exporting advanced, automated, and energy-efficient filter presses to global markets.

Conclusion: Automation for a Cleaner, Smarter Future

An Automatic Hydraulic Filter Press is more than a piece of equipment—it’s an investment in smarter, cleaner production. By automating solid–liquid separation, it helps industries minimize waste, recover valuable resources, and operate sustainably.

Partnering directly with a China manufacturer capable of bulk supply ensures not only cost-effective procurement but also access to engineering expertise and flexible customization.

For modern plants seeking higher productivity, resource efficiency, and reliability, adopting a Hydraulic Filter Press system marks a clear step toward sustainable, intelligent industrial development.

References

GB/T 7714:Teutscher D, Weber-Carstanjen T, Simonis S, et al. Predicting Filter Medium Performances in Chamber Filter Presses with Digital Twins Using Neural Network Technologies[J]. Applied Sciences, 2025, 15(9): 4933.

MLA:Teutscher, Dennis, et al. "Predicting Filter Medium Performances in Chamber Filter Presses with Digital Twins Using Neural Network Technologies." Applied Sciences 15.9 (2025): 4933.

APA:Teutscher, D., Weber-Carstanjen, T., Simonis, S., & Krause, M. J. (2025). Predicting Filter Medium Performances in Chamber Filter Presses with Digital Twins Using Neural Network Technologies. Applied Sciences, 15(9), 4933.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province