NewsDetails

Chamber Filter Press vs. Other Filtration Methods

author:Shuangcheng time:2025-09-17 22:52:59 Click:81

Choosing the Right Filtration System

In industries where solid-liquid separation is routine—such as wastewater treatment, mining, food processing, and chemicals—the performance of your filtration system directly impacts operating efficiency and costs. The Chamber Filter Press has gained popularity because of its proven reliability and low running expenses.

For companies looking to control budgets without sacrificing quality, working with a China factory or China supplier is often the preferred choice. Bulk production capabilities ensure competitive prices and continuous supply for large-scale projects.

Understanding the Chamber Filter Press

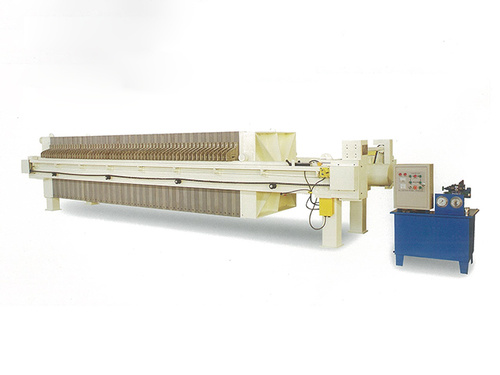

At its core, the Chamber Filter Press consists of plates lined with filter cloths that capture solids while permitting liquids to pass through. The outcome is a compact filter cake with reduced moisture content.

Main strengths include:

·Exceptional solid recovery efficiency

·Low residual water in cakes

·Straightforward operation and maintenance

·Adaptability across a wide range of slurries

How It Stacks Up Against Other Systems

Chamber Filter Press vs. Belt Filter Press

·Chamber Filter Press: Creates much drier cakes and takes up less floor space.

·Belt Filter Press: Works continuously but results in wetter cake and requires more footprint.

Chamber Filter Press vs. Centrifuge

·Chamber Filter Press: More energy-efficient with lower long-term costs.

·Centrifuge: Handles high volumes quickly but has higher maintenance and power demands.

Chamber Filter Press vs. Vacuum Filtration

·Chamber Filter Press: Produces dry solids and requires minimal monitoring.

·Vacuum Filtration: Useful for finer particles but typically less efficient in moisture reduction.

Chamber Filter Press vs. Cartridge Filters

·Chamber Filter Press: Suitable for industrial-scale needs with high slurry volumes.

·Cartridge Filters: Designed for smaller applications or laboratory-scale processes.

Why the Chamber Filter Press Leads the Market

Industries choose this system because it consistently balances cost with performance.

Typical applications include:

·Mining and mineral extraction

·Municipal wastewater treatment plants

·Food and beverage industry

·Chemical and pharmaceutical facilities

Its longevity and ability to deliver uniform filtration make it a preferred investment.

Benefits of Choosing a China Supplier or Factory

Global contractors often rely on China manufacturers because:

·Bulk Capacity: Large production lines mean reliable supply even for urgent or large orders.

·Cost Advantage: Direct supply cuts intermediaries, lowering procurement expenses.

·Tailored Options: Many factories provide custom-built filter press configurations.

·International Certification: Products often comply with ISO, CE, and similar global standards.

This combination of affordability and compliance gives Chinese suppliers a strong advantage in the global market.

Keeping the Chamber Filter Press in Good Condition

Proper maintenance is essential to ensure long service life:

·Inspect filter cloths frequently to prevent clogging.

·Clean plates and chambers after every operation.

·Check hydraulic systems regularly for pressure stability.

·Keep replacement parts on hand to reduce downtime.

Consistent upkeep ensures the unit runs at peak performance for years.

Conclusion: Why the Chamber Filter Press Is a Smart Choice

When comparing filtration methods, the Chamber Filter Press clearly provides superior cake dryness, energy savings, and long-term dependability. Its efficiency surpasses belt presses, centrifuges, and other systems in many industrial environments.

For businesses scaling up operations, sourcing through a China supplier or China factory means affordable bulk supply, dependable logistics, and equipment that meets international quality expectations.

By selecting a Chamber Filter Press, you are not only investing in effective separation but also ensuring sustainable performance and reduced operational costs.

References

GB/T 7714:Wastewater treatment plant design[M]. IWA publishing, 2003.

MLA:Vesilind, P., ed. Wastewater treatment plant design. Vol. 2. IWA publishing, 2003.

APA:Vesilind, P. (Ed.). (2003). Wastewater treatment plant design (Vol. 2). IWA publishing.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province