NewsDetails

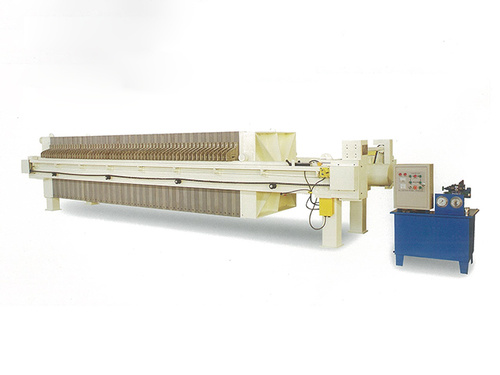

Chamber Filter Press Working Principle Explained for Industrial Use

author:Shuangcheng time:2025-09-11 21:05:59 Click:60

Why Chamber Filter Press Is a Reliable Choice

In industries where solid-liquid separation is essential, the Chamber Filter Press has earned its reputation as a reliable and efficient solution. By producing dry cakes, cutting waste management costs, and handling a wide range of slurries, this equipment has become a standard in modern industrial filtration.

Buyers often partner with China suppliers and Chinese manufacturers that demonstrate bulk supply capabilities to secure both quality machinery and consistent delivery.

Chamber Filter Press Working Principle

The working principle of a Chamber Filter Press can be summarized in a few key steps:

1.Plate Alignment: Recessed filter plates are pressed together, forming sealed chambers.

2.Slurry Filling: Slurry is pumped into these chambers under pressure.

3.Filtration Process: Filter cloths allow liquid to pass through while trapping solid particles.

4.Cake Development: Solids accumulate in each chamber and gradually form compact filter cakes.

5.Discharge Stage: When filtration ends, plates are separated, and the cakes are discharged.

This batch-based operation ensures efficient removal of solids, resulting in cleaner liquid output and drier waste cakes.

Key Advantages of Chamber Filter Press

1. Efficient Solid-Liquid Separation

The system delivers lower moisture content in cakes, reducing both disposal weight and transportation costs.

2. Cost-Effective Operation

With simple mechanics and modest energy needs, the chamber press provides long-term savings.

3. Wide Application Range

It handles diverse slurries, from mining tailings to chemical residues and food-processing byproducts.

4. Compact but Powerful

Despite its relatively small footprint, it processes high volumes of slurry, making it ideal for facilities with limited space.

5. Long-Term Reliability

Built with durability in mind, a Chamber Filter Press has fewer moving parts, meaning less maintenance and longer service life.

Industrial Applications of Chamber Filter Press

The adaptability of chamber presses explains their global popularity across industries:

·Mining and Metallurgy: Concentrate and tailings dewatering.

·Municipal Wastewater: Sludge treatment and volume reduction.

·Chemical Industry: Processing catalysts, pigments, and process residues.

·Food and Beverage: Clarifying juices, sugar refining, and starch recovery.

In each case, the chamber press provides consistent performance while lowering operating costs.

Why Work with China Suppliers and Chinese Manufacturers

For businesses sourcing filtration equipment, reliable China suppliers and Chinese manufacturers bring distinct advantages:

·Bulk Supply Assurance: Ability to deliver large orders without compromising quality.

·Competitive Pricing: Cost-effective solutions backed by industrial expertise.

·Customization Options: Press designs can be adapted to unique industry requirements.

·Global Standards: Many manufacturers comply with ISO and CE certifications, ensuring international quality benchmarks.

Partnering with suppliers who have proven bulk supply capability ensures both immediate performance and long-term reliability.

Conclusion: Secure Performance with Chamber Filter Press

The Chamber Filter Press stands out as a powerful, cost-saving, and versatile system for solid-liquid separation. Its straightforward working principle, combined with advantages in efficiency and reliability, makes it indispensable across industries.

When sourced from experienced China suppliers or Chinese manufacturers with the capacity for bulk supply, businesses not only obtain durable equipment but also ensure lasting value and dependable support.

Investing in a Chamber Filter Press today is a step toward more sustainable, efficient, and profitable industrial operations.

References

GB/T 7714:Tosoni J, Baudez J C, Girault R. Effect of operating parameters on the dewatering performance of press filters: a sensitivity analysis[J]. Drying Technology, 2015, 33(11): 1327-1338.

MLA:Tosoni, Julian, Jean-Christophe Baudez, and Romain Girault. "Effect of operating parameters on the dewatering performance of press filters: a sensitivity analysis." Drying Technology 33.11 (2015): 1327-1338.

APA:Tosoni, J., Baudez, J. C., & Girault, R. (2015). Effect of operating parameters on the dewatering performance of press filters: a sensitivity analysis. Drying Technology, 33(11), 1327-1338.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province