NewsDetails

Chamber Geometry and Its Impact on Filtration Quality

author:Shuangcheng time:2025-12-12 10:22:43 Click:61

Why Chamber Design Shapes Filtration Outcomes

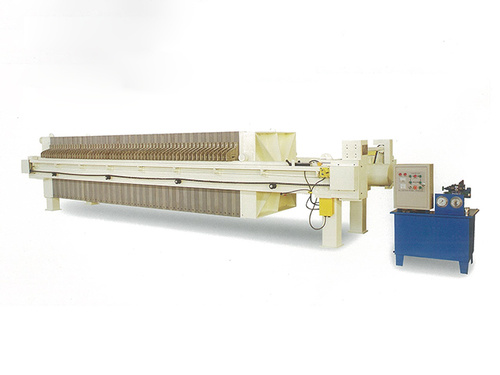

Across modern industrial processes, the Chamber Filter Press has become a cornerstone technology for achieving dependable solid–liquid separation. Its popularity comes from its reliability and high-quality filtration results. While many factors—such as feed pressure, filter cloth type, and slurry characteristics—affect overall performance, the geometry of the chamber plays a defining role.

This is precisely why companies often collaborate with a filtration equipment manufacturer that has strong engineering, stable production, and consistent bulk supply capability to ensure chamber quality remains uniform across large-scale operations.

Understanding the Core Geometry of Chamber Filtration

The geometry of a filtration chamber refers not only to its physical dimensions but also to the internal configuration that guides how slurry flows, how solids settle, and how filtrate exits. Major elements of chamber geometry include:

Plate Cavities

Symmetrical cavities determine the available space for cake formation. Variations in depth influence how much material the chamber can hold.

Drainage Channels

These channels enable filtrate to pass through efficiently. Their pattern and angle affect speed, pressure, and clarity.

Feed Port Arrangement

An optimally placed feed port ensures the slurry spreads uniformly rather than concentrating in one area.

Surface Topography

Raised patterns, ridges, or ribs on plate surfaces provide structural integrity and help the filter cloth stay in place during pressure cycles.

Scientific Mechanics Behind Chamber-Driven Separation

1. Fluid Flow Path Optimization

The chamber’s internal layout determines how the feed slurry moves. Smooth transitions and symmetrical chamber volume reduce turbulence, allowing particles to settle and compact consistently.

2. Pressure Distribution

Mechanical compression forces must be transmitted evenly across the chamber. Poor geometry leads to imbalances, causing uneven cake thickness or localized stress on the filter cloth.

3. Cake Growth Dynamics

As the cake builds, its resistance changes. A well-designed chamber promotes uniform growth, which stabilizes filtration velocity and reduces backpressure.

4. Filtrate Release Efficiency

The chamber must allow filtrate to escape without restrictions. Proper geometry reduces hydraulic resistance, improving clarity and lowering energy consumption.

The Direct Link Between Chamber Shape and Filtration Quality

Improved Cake Structure

A precisely shaped chamber promotes an even distribution of solids. The result is a cake with predictable density, thickness, and moisture content—critical for downstream handling or product specification.

Higher Clarity and Purity

When geometry supports consistent pressure and tight sealing, the amount of solids bypassing the cloth decreases. This enhances clarity, which is vital for applications requiring high-quality filtrate.

Optimized Cycle Time

Efficient drainage and balanced cake formation shorten filtration cycles, allowing more batches to be processed in the same timeframe.

Lower Cloth Wear and Maintenance

Proper geometry reduces misalignment and uneven force, extending the lifespan of filter cloths and minimizing unexpected downtime.

Reliable Repeatability

Repeatability is crucial for large manufacturing operations. A geometrically stable chamber ensures every filtration cycle produces similar results, enhancing process control and quality assurance.

Real-World Effects Across Industrial Applications

Chemical and Process Industries

Precise chamber geometry ensures reactions downstream receive consistent feed material. Variations can influence purity, viscosity, and color stability.

Food and Beverage

For edible oils, juices, starches, and sweeteners, uniform chamber performance helps maintain flavor consistency and clarity.

Mining and Mineral Processing

High-solids slurries need chambers that can handle dense materials without clogging or deformation.

Environmental Filtration

Wastewater treatment plants benefit from chambers that extract more liquid from sludge, reducing disposal costs.

Pharmaceutical and Biotech

Regulated industries require absolute consistency. Chamber geometry directly affects compliance and batch validation.

Selecting the Right Chamber Geometry for Consistent Output

Match Geometry to Particle Size and Behavior

Fine powders, fibrous materials, and crystalline particles each respond differently under pressure. Proper geometry mitigates clogging and improves efficiency.

Consider Cake Dryness Requirements

Some industries require extremely dry cakes for ease of disposal or further processing. Chamber depth and drainage angles must support that goal.

Evaluate Throughput Needs

If the goal is high-volume production, select geometries designed for rapid drainage and minimal resistance.

Work With a Reliable Manufacturer

Choosing a manufacturer capable of precision machining, consistent quality control, and steady bulk supply ensures that chamber geometry remains accurate across every unit produced.

Final Insights: Strengthening Quality With a Chamber Filter Press

A well-engineered Chamber Filter Press owes much of its performance to carefully designed chamber geometry. The chamber’s structure dictates filtration speed, clarity, cake dryness, and overall operational stability. By using equipment produced by a reliable manufacturer with strong production and bulk-supply capacity, industries can optimize filtration quality, ensure long-term reliability, and significantly enhance process efficiency.

References

GB/T 7714:Perry J H. Chemical engineers' handbook[J]. 1950.

MLA:Perry, John H. "Chemical engineers' handbook." (1950): 533.

APA:Perry, J. H. (1950). Chemical engineers' handbook.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province