NewsDetails

Chemical Industry Applications of Hydraulic Filter Press

author:Shuangcheng time:2026-01-08 15:00:03 Click:175

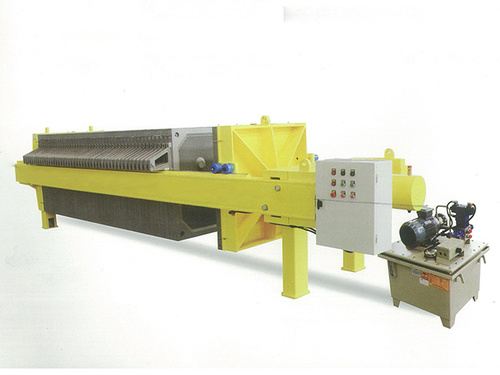

Hydraulic Filter Press in Chemical Processing

In the chemical industry, solid-liquid separation is a critical process that directly impacts product purity, operational efficiency, and environmental compliance. A hydraulic filter press is widely used in chemical processing due to its ability to deliver stable pressure, controlled filtration cycles, and consistent cake formation under demanding conditions.

From a manufacturer and production perspective, hydraulic filter press systems are designed to support continuous operation, batch consistency, and bulk processing requirements. Their adaptability makes them suitable for a wide range of chemical applications, including fine chemicals, specialty compounds, and intermediate processing stages.

When applied correctly, a hydraulic filter press helps chemical producers maintain filtration reliability while supporting scalable production and long-term equipment performance.

Why Hydraulic Filter Press Is Essential for Chemical Applications

Chemical processing environments often involve aggressive media, fine particulates, and strict separation standards. Hydraulic filter press systems are engineered to meet these challenges through controlled mechanical force and precise pressure regulation.

Key advantages include:

·Stable hydraulic pressure throughout filtration cycles

·Uniform cake thickness for predictable separation

·Compatibility with chemically resistant materials

·Reduced manual intervention during operation

For chemical manufacturers operating at scale, these features translate into consistent output quality and reduced process variability.

Working Principle in Chemical Filtration Processes

A hydraulic filter press operates by applying pressure through a hydraulic system that compresses filter plates together. Slurry is pumped into the chambers, where solids are retained by filter media while liquid passes through as filtrate.

In chemical applications, this process supports:

·High filtration accuracy for fine chemical particles

·Controlled pressure buildup to prevent media damage

·Reliable separation even with variable feed characteristics

From a production standpoint, hydraulic systems provide repeatable closing force, ensuring consistent filtration behavior across multiple production cycles.

Chemical Industry Use Cases

Filtration of Chemical Slurries

Chemical slurries often contain fine particles that require precise separation. Hydraulic filter press systems are suitable for handling varying solid concentrations while maintaining filtration efficiency.

Applications include:

·Intermediate chemical processing

·Catalyst recovery

·Pigment and dye production

The controlled pressure profile supports effective dewatering without compromising chemical integrity.

Wastewater and Byproduct Treatment

Chemical plants generate wastewater streams that require solid-liquid separation before discharge or reuse. Hydraulic filter press systems support:

·Sludge volume reduction

·Improved cake dryness

·Easier downstream handling

These benefits align with environmental compliance requirements and cost-effective waste management strategies.

Material Compatibility and System Design

Chemical environments demand materials that resist corrosion, chemical attack, and thermal stress. Hydraulic filter press systems can be configured with materials selected for chemical compatibility, ensuring long service life.

Design considerations include:

·Filter plate material selection

·Seal and gasket resistance

·Structural stability under continuous pressure

From a manufacturer perspective, standardized production processes ensure material consistency across bulk equipment supply, supporting reliable long-term operation.

Integration into Chemical Production Lines

Hydraulic filter press systems are commonly integrated into automated or semi-automated chemical production lines. Their hydraulic closing mechanisms allow precise control and repeatability.

Integration benefits include:

·Compatibility with upstream reactors and mixers

·Reduced manual handling

·Improved production line efficiency

For large-scale chemical operations, seamless integration supports higher throughput without sacrificing filtration quality.

Manufacturing and Production Considerations

From a hydraulic filter press manufacturer standpoint, chemical industry applications require equipment designed for durability, repeatability, and scalable production.

Key production factors include:

·Precision machining for hydraulic components

·Consistent plate alignment and sealing

·Structural reinforcement for long-term pressure cycles

Production-level quality control ensures that each hydraulic filter press unit delivers predictable performance across bulk supply orders.

Bulk Supply and Operational Consistency

Chemical manufacturers often require multiple filter press units for parallel processing or facility expansion. Hydraulic filter press systems designed for bulk production ensure uniform performance across all supplied units.

Benefits of manufacturer-level bulk supply include:

·Standardized equipment specifications

·Simplified maintenance and spare parts management

·Predictable filtration results across production lines

This consistency supports long-term operational planning and cost control in chemical processing facilities.

Conclusion: Hydraulic Filter Press as a Strategic Asset in Chemicals

The hydraulic filter press plays a vital role in chemical industry filtration, offering controlled pressure, consistent separation performance, and compatibility with demanding processing environments. Its ability to handle diverse chemical slurries while maintaining operational stability makes it a core component of modern chemical production systems.

From a manufacturer and production perspective, hydraulic filter press solutions designed for bulk supply and industrial-scale use provide chemical producers with reliability, scalability, and long-term value. When properly integrated, hydraulic filter press systems become more than filtration equipment—they serve as strategic assets supporting efficient chemical processing and sustainable production growth.

References

GB/T 7714:Wakeman R, Tarleton E S. Solid/liquid separation: principles of industrial filtration[M]. Elsevier, 2005.

MLA:Wakeman, Richard, and E. Steve Tarleton. Solid/liquid separation: principles of industrial filtration. Elsevier, 2005.

APA:Wakeman, R., & Tarleton, E. S. (2005). Solid/liquid separation: principles of industrial filtration. Elsevier.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province