NewsDetails

Choosing the Right Plates for Your Hydraulic Filter Press

author:Shuangcheng time:2025-10-31 01:31:11 Click:141

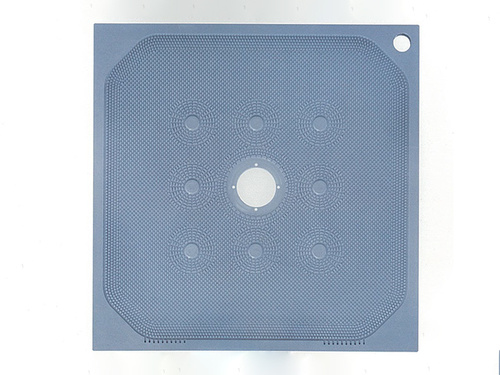

In any Hydraulic Filter Press, the plates are the true heart of the system. They define how effectively liquid is separated from solids, how dry the final cake becomes, and how long the equipment operates without issues.

Many operators focus on pumps or frames, but in reality, filter plates are the main drivers of consistency and filtration quality. Selecting the right type ensures smooth operation, fewer maintenance interruptions, and optimal throughput.

For industrial-scale operations, obtaining Hydraulic Filter Press plates directly from a China manufacturer—especially one offering bulk production and export capability—is an excellent way to guarantee quality control and competitive pricing.

1. Why Plate Selection Matters

Every filtration cycle subjects plates to intense hydraulic pressure, temperature changes, and chemical stress. Poor-quality or mismatched plates can cause uneven cake buildup, slurry leakage, or rapid material degradation.

When correctly selected, plates ensure:

·Uniform pressure distribution throughout the chambers.

·Consistent cake dryness across cycles.

·Stable operation under high mechanical load.

·Simplified cleaning and maintenance procedures.

Essentially, well-chosen plates transform a standard press into a long-lasting, high-performance filtration machine.

2. Plate Material Comparison

The best plate depends on what kind of slurry you process and under what conditions. Here’s how the main materials differ:

Polypropylene (PP)

Lightweight, affordable, and resistant to most chemicals. Ideal for wastewater and general industrial use. PP plates don’t corrode, and their smooth surface simplifies cake release.

Cast Iron

Tough and pressure-tolerant, often used in mining and metallurgical applications. While extremely strong, these plates need periodic maintenance to prevent surface rust.

Stainless Steel

Perfect for high-temperature or food-grade operations. It withstands chemical corrosion and heat, making it common in pharmaceuticals and chemical filtration systems.

Membrane Plates

A hybrid type made of PP or metal with an elastic membrane layer. When inflated, the membrane squeezes the cake for higher dryness—boosting efficiency while cutting cycle time.

3. Key Plate Designs and Their Uses

The geometry and internal design of a plate affect how efficiently it handles pressure and flow:

·Recessed Chamber Plates: The most standard option—durable and easy to maintain. Good for general filtration where throughput is prioritized.

·Membrane Plates: Used when moisture content must be minimized; ideal for sludge dewatering or precision chemical processes.

·Plate and Frame Design: Offers the highest filtration clarity. Common in fine chemical and biotech industries where purity is critical.

Each design influences how quickly filtrate exits, how uniformly pressure is distributed, and how the cakes are discharged.

4. Technical Factors When Choosing Plates

Before finalizing your purchase, consider these technical points to match your system’s requirements:

1.Filtration Pressure: The plate must handle the system’s rated pressure safely.

2.Slurry Composition: Corrosive slurries demand stainless or coated plates.

3.Operating Temperature: High-heat applications require materials with low expansion rates.

4.Cycle Frequency: Frequent cycles benefit from low-weight plates for easier handling.

5.Cleaning Needs: Smooth plates minimize residue accumulation and simplify washing.

Professional China manufacturers can assist with these specifications and produce custom plate configurations in bulk, ensuring performance and longevity.

5. Maintenance Practices for Longer Plate Life

Even the strongest plates wear down without proper maintenance. Routine checks and cleaning routines significantly extend service life.

·Inspect plates frequently: Look for cracks, warping, or seal deformation.

·Clean after each cycle: Residual solids can harden, damaging sealing edges.

·Avoid over-pressurizing: Excessive force leads to permanent bending.

·Store correctly: Keep plates dry and flat when not in use to prevent distortion.

Consistent maintenance keeps filtration efficiency stable and minimizes unplanned downtime.

6. Advantages of Partnering with a China Manufacturer

When sourcing Hydraulic Filter Press plates, quality consistency and scalability are essential. A trusted China manufacturer with bulk supply capacity offers major benefits:

·High-precision molding and material blending technology.

·Mass production with ISO-certified quality systems.

·Custom size and thickness options for different press models.

·Favorable cost structure—ideal for large procurement projects.

·Stable global export and technical after-sales support.

These capabilities make China a dependable hub for industrial filtration solutions, providing reliability and long-term supply stability at scale.

Conclusion

Selecting the correct Hydraulic Filter Press plates is not a minor detail—it’s a strategic decision that directly influences efficiency, product quality, and maintenance costs.

Whether you’re operating a wastewater plant, chemical facility, or mining project, pairing your system with high-grade plates from a reputable China manufacturer offering bulk supply ensures lasting performance and smoother operations.

In the world of hydraulic filtration, precision-built plates aren’t just components—they’re the key to sustainable productivity and cleaner results.

References

GB/T 7714:Chang H, Zhao Y, Xu A, et al. Mini-review of inventory data for the dewatering and drying of sewage sludge[J]. Waste Management & Research, 2023, 41(6): 1081-1088.

MLA:Chang, Huimin, et al. "Mini-review of inventory data for the dewatering and drying of sewage sludge." Waste Management & Research 41.6 (2023): 1081-1088.

APA:Chang, H., Zhao, Y., Xu, A., Damgaard, A., & Christensen, T. H. (2023). Mini-review of inventory data for the dewatering and drying of sewage sludge. Waste Management & Research, 41(6), 1081-1088.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province