NewsDetails

How Chamber Filtration Enhances Efficiency in Solid-Liquid Separation

author:Shuangcheng time:2025-12-06 09:25:51 Click:147

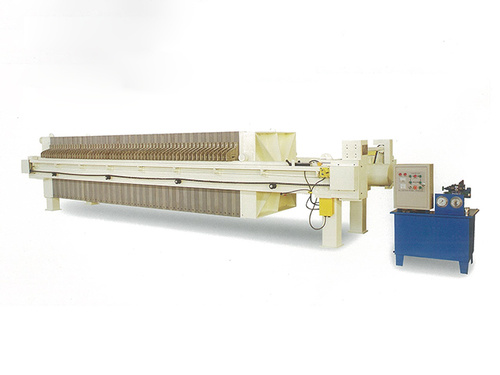

A Chamber Filter Press plays an essential role in modern industrial separation processes, especially for facilities that depend on stable dewatering performance and high-clarity filtrate. For companies sourcing equipment directly from a professional Manufacturer with reliable Production capacity, understanding how chamber-style filtration improves efficiency is critical for optimizing long-term operational output.

This article explores the working behavior of chamber filtration, the structural features that support its performance, and the practical advantages it provides in solid-liquid separation applications across major industries.

How Chamber Filtration Operates in a Chamber Filter Press

Chamber filtration relies on a series of recessed filter plates arranged to form sealed chambers. When slurry is pumped into the press under pressure:

·The liquid phase passes through the filter cloth and becomes filtrate.

·Solid particles remain inside the chamber, gradually forming a compact filter cake.

·As the chamber fills, pressure increases, compressing the cake to a lower moisture level.

The geometry of the chambers ensures consistent cake buildup and stable filtration pressure, which is why this system is preferred for demanding industrial processes.

Why Chamber Filtration Improves Solid-Liquid Separation Efficiency

1. High Pressure Enables Faster Filtration Cycles

Because a Chamber Filter Press can sustain elevated filtration pressures, it processes thick or hard-to-filter slurries more effectively. The result is:

·Shorter cycle times

·Increased daily throughput

·More efficient handling of viscous materials

Industries dealing with minerals, chemical slurries, or wastewater benefit the most from this pressure-driven efficiency.

2. Uniform Cake Formation Produces More Consistent Results

The chamber layout encourages solids to settle in an even pattern. This uniformity helps:

·Reduce channeling

·Maintain predictable filtration rates

·Improve cake dryness and clarity

Consistent performance is especially important for processes that require reliable filtration quality during continuous production.

3. Superior Dewatering Performance

Chamber Filter Press designs support balanced pressure across all plates. This minimizes moisture retention and enhances the dryness of the final cake, which:

·Reduces waste handling costs

·Improves the value of recovered solids

·Supports stricter environmental discharge standards

In many industries, moisture reduction alone can meaningfully improve overall operational economics.

4. Lower Total Energy Use

Despite operating at high pressure, chamber systems often consume less energy because their efficiency reduces the number of pumping hours required. Benefits include:

·Less wear on pumps

·Reduced electricity consumption

·Lower lifetime operating costs

This energy advantage is noticeable in high-volume processing plants.

5. Flexible and Scalable Structural Design

The modular nature of chamber filtration allows facilities to adjust capacity simply by adding or removing plates. This adaptability ensures:

·Easy system expansion

·Customization for process changes

·Long-term equipment compatibility

For Manufacturers providing bulk Production supply, this modularity makes Chamber Filter Presses suitable for diverse applications.

Structural Features That Enhance Filtration Efficiency

• Reinforced Filter Plates

The plates in a Chamber Filter Press are engineered to withstand repeated high-pressure cycles without warping. This durability ensures:

·Consistent sealing

·Stable pressure distribution

·Long operational lifespan

Strong plate structure is fundamental to reliable industrial filtration.

• High-Performance Filter Cloth

Filter cloth selection directly affects filtration efficiency. Chamber systems typically use engineered fabrics designed for:

·High permeability

·Abrasion resistance

·Chemical compatibility

An optimized cloth reduces clogging, maintains stable filtration flow, and improves final filtrate quality.

• Robust Hydraulic Closing Mechanism

Most Chamber Filter Presses use hydraulic systems to clamp plates tightly into position. A stable hydraulic mechanism ensures:

·Proper alignment

·Secure sealing during pressurization

·Safe operation at high loads

This contributes to consistent performance and longer equipment life.

How Chamber Filtration Improves Overall Production Stability

Implementing a Chamber Filter Press not only boosts separation efficiency but also enhances the general stability of industrial workflows. Benefits include:

·Lower downtime caused by inconsistent filtration

·Better control of filtrate quality

·Reduced cleaning frequency

·More predictable output in continuous processing environments

This combination makes chamber filtration one of the most reliable methods for modern solid-liquid separation.

Final Thoughts

For operations looking to strengthen their separation performance, the Chamber Filter Press remains a proven and efficient solution. Its chamber-based structure provides stronger dewatering capabilities, faster cycle times, and higher filtration accuracy—qualities highly valued across mining, chemical, food, and environmental industries.

When selecting equipment from a skilled Manufacturer with stable Production capability, understanding how chamber filtration enhances efficiency will help ensure you choose the most suitable system and achieve long-term operational gains.

References

GB/T 7714:Wakeman R, Tarleton E S. Solid/liquid separation: principles of industrial filtration[M]. Elsevier, 2005.

MLA:Wakeman, Richard, and E. Steve Tarleton. Solid/liquid separation: principles of industrial filtration. Elsevier, 2005.

APA:Wakeman, R., & Tarleton, E. S. (2005). Solid/liquid separation: principles of industrial filtration. Elsevier.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province