NewsDetails

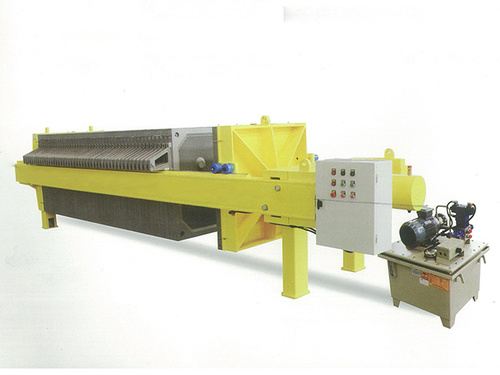

Hydraulic Filter Press in Metallurgy: Efficiency Boosts

author:Shuangcheng time:2025-11-03 01:59:54 Click:77

In the field of metallurgy, where precision and efficiency directly impact profitability, filtration systems play a crucial role in separating solids from process fluids. Among all available technologies, the Hydraulic Filter Press has proven to be one of the most effective tools for achieving high-performance dewatering and metal recovery.

From copper and zinc processing to iron and steel by-product management, the hydraulic press improves both productivity and sustainability. Selecting high-quality systems—especially those produced by a China manufacturer with bulk supply capacity—ensures operational stability, reduced downtime, and significant cost control across the production line.

1. The Core Function of Hydraulic Filter Press in Metallurgy

The Hydraulic Filter Press works by applying uniform hydraulic pressure to force liquid through a porous medium, capturing solid particles inside each chamber. In metallurgical processes, this technology is used to treat concentrates, tailings, and effluents that contain valuable metals or fine mineral particles.

The result is a dense, compact filter cake with minimal residual moisture and a clarified filtrate ready for reuse. Properly configured presses not only enhance recovery efficiency but also reduce waste disposal volumes—an essential factor for plants aiming to meet environmental compliance.

2. Key Advantages in Metallurgical Operations

a. Maximized Metal Yield

Precise pressure and plate alignment ensure minimal metal loss in liquid waste streams. The high-density cakes produced by these systems retain even the finest metal particles, maximizing recovery.

b. Energy Efficiency

Lower moisture in the filter cake means less energy is needed for drying or smelting. Recycled filtrate also decreases water consumption, improving the plant’s sustainability profile.

c. Long-Term Durability

Built to endure high pressure, temperature, and chemical exposure, modern Hydraulic Filter Press metallurgy systems operate reliably under the demanding conditions of industrial metal extraction.

d. Compliance and Sustainability

Cleaner discharge and reduced sludge volumes make hydraulic filtration systems an eco-conscious choice, helping operators meet strict environmental and waste regulations.

3. Plate Selection and Material Optimization

The performance of a filter press depends heavily on the type of plates it uses. Metallurgical slurries differ widely in composition, so choosing the correct plate material is critical.

·Polypropylene Plates (PP): Corrosion-resistant and lightweight, ideal for chemical and metal wastewater applications.

·Membrane Plates: Designed for high-efficiency squeezing, reducing cake moisture to as low as 20%.

·Cast Iron or Steel Plates: Provide exceptional strength for dense or abrasive tailings in mining and heavy metal processing.

Each plate type influences cycle speed, cake uniformity, and energy use. Working with a China manufacturer allows buyers to customize materials, size, and chamber depth according to process requirements.

4. Operational Parameters for Higher Efficiency

Even with a strong filtration unit, efficiency depends on process control. Optimal Hydraulic Filter Press performance requires attention to key parameters:

·Feed Pressure: Too low results in incomplete filtration; too high may damage plates.

·Cycle Duration: Finding the right pressing time balances throughput and cake dryness.

·Cake Washing Process: Essential when recovering valuable metals from concentrate slurries.

·Regular Cleaning: Prevents clogging, maintains permeability, and extends filter cloth life.

Tuning these factors ensures consistent filtration cycles and stable metallurgical performance.

5. Why Choose China Manufacturers for Filter Press Supply

In recent years, China manufacturers have become global leaders in Hydraulic Filter Press design and production. Their equipment combines affordability with precision, serving metallurgy, mining, and wastewater industries worldwide.

Advantages of partnering with a China-based bulk supplier include:

·Mass production with ISO-certified quality assurance.

·Customizable configurations for different metals, slurry types, and capacities.

·Advanced hydraulic control systems for stable pressure and automation.

·Strong export logistics and consistent after-sales technical support.

Bulk manufacturing not only reduces cost per unit but also guarantees product consistency—critical for metallurgical plants operating around the clock.

6. Maintenance Practices for Longevity

Maintenance directly affects the service life of a hydraulic press. Even high-grade equipment requires regular checks to ensure performance remains optimal.

Routine recommendations include:

·Inspecting for leaks, cracks, or worn seals before each cycle.

·Cleaning plates and cloths to prevent buildup of solid residues.

·Monitoring hydraulic pressure to avoid system overload.

·Replacing filter media when permeability drops.

With proper maintenance and periodic inspection, a well-designed Hydraulic Filter Press can operate efficiently for more than a decade, minimizing unexpected downtime.

Conclusion

Efficiency in metallurgy depends on precise control of every production stage—and filtration is no exception. The Hydraulic Filter Press has redefined industrial dewatering by combining power, precision, and environmental responsibility.

Whether for metal concentrate recovery or tailings treatment, sourcing your system from a reputable China manufacturer with bulk supply capacity guarantees high-quality engineering, cost efficiency, and global technical support.

In today’s competitive metallurgical industry, reliable filtration isn’t just a technical requirement—it’s a strategic advantage that drives cleaner, faster, and more sustainable production.

References

GB/T 7714:Chang H, Zhao Y, Xu A, et al. Mini-review of inventory data for the dewatering and drying of sewage sludge[J]. Waste Management & Research, 2023, 41(6): 1081-1088.

MLA:Chang, Huimin, et al. "Mini-review of inventory data for the dewatering and drying of sewage sludge." Waste Management & Research 41.6 (2023): 1081-1088.

APA:Chang, H., Zhao, Y., Xu, A., Damgaard, A., & Christensen, T. H. (2023). Mini-review of inventory data for the dewatering and drying of sewage sludge. Waste Management & Research, 41(6), 1081-1088.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province