NewsDetails

Hydraulic Filter Press in Wastewater Treatment: Key Advantages

author:Shuangcheng time:2025-11-06 04:18:46 Click:158

Meeting the Demand for Cleaner Industrial Water

Industrial wastewater is one of the most challenging forms of waste to manage, containing suspended solids, heavy metals, and organic residues. As environmental standards become stricter, industries must adopt reliable, energy-efficient methods to separate solids from liquid waste.

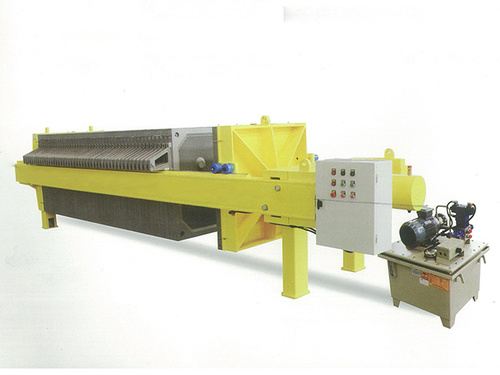

Among available technologies, the Hydraulic Filter Press has proven to be one of the most practical and durable systems.

Today, many China-based hydraulic filter press manufacturers supply bulk production units that combine strong dewatering capacity with long service life—an essential feature for chemical, textile, and food-processing industries striving for sustainability and compliance.

1. The Working Principle of a Hydraulic Filter Press

A Hydraulic Filter Press operates by applying controlled hydraulic pressure to a sequence of filter plates lined with filtration cloths. The sludge is pumped into chambers, where liquid passes through the cloths, leaving behind a compact “cake” of solids.

Key Features Include:

·Hydraulic cylinders that maintain uniform pressure.

·Polypropylene or stainless-steel filter plates for corrosion resistance.

·Automated plate shifting to reduce downtime and manual labor.

·Integrated PLC control for consistent cycle timing.

This system ensures precise separation performance even with high-viscosity industrial slurries, making it indispensable in wastewater applications.

2. Role in Modern Wastewater Treatment Systems

In most treatment plants, the hydraulic press serves as the final dewatering stage after thickening or chemical conditioning.

The process typically involves:

1.Feeding the sludge: Pumping semi-solid waste into the press.

2.Filtration: Hydraulic pressure forces water through the cloths.

3.Cake formation: Solids compress into dense cakes with minimal moisture.

4.Cake discharge: Plates open automatically, and cakes are released for safe disposal or reuse.

The filtrate water, often clear and particle-free, can be recycled back into the process or discharged with minimal treatment, saving both water and energy.

3. Major Benefits of Hydraulic Filter Presses in Wastewater Operations

a. High Dewatering Efficiency

By using uniform hydraulic pressure, these systems achieve dryness levels superior to belt filters or decanter centrifuges, cutting disposal costs significantly.

b. Energy and Cost Savings

Hydraulic presses consume little power because they operate in controlled cycles. Their mechanical simplicity minimizes the need for replacement parts and operator supervision.

c. Reliable Filtrate Quality

The filtration cloth ensures that fine suspended solids are trapped, producing clean filtrate suitable for reuse in non-critical operations.

d. Compact and Automated Design

The vertical stacking and automatic control system make hydraulic presses ideal for plants with limited floor space or labor resources.

e. Sustainable Waste Management

Reduced sludge volume means less landfill burden, while efficient water recovery supports environmental responsibility goals.

4. Industrial Fields Benefiting from Hydraulic Filter Presses

Hydraulic filter presses are now integral to wastewater treatment in industries such as:

·Metal plating and electro-galvanizing – removing metallic hydroxides and heavy particles.

·Textile dyeing and finishing – filtering pigments, fibers, and dye residues.

·Food and beverage production – managing organic residues from juice, wine, and fermentation.

·Chemical and pharmaceutical plants – handling fine slurry separation under sterile conditions.

Each industry benefits from the press’s high adaptability and proven mechanical reliability.

5. Why Partner with a China Hydraulic Filter Press Manufacturer

China’s industrial filtration sector has become a global center for cost-effective and certified solutions. Choosing a China supplier offers numerous advantages:

·Mass production and bulk availability, ideal for global distributors.

·Competitive pricing through direct factory supply chains.

·Compliance with CE, ISO, and food-grade standards.

·Tailored engineering services to suit client-specific wastewater compositions.

·Comprehensive technical support—from installation to long-term maintenance.

Working directly with a China hydraulic filter press manufacturer ensures continuous support, fast logistics, and scalable production for industrial clients worldwide.

6. Selecting the Right Model for Your Treatment Line

When sourcing a filter press, consider:

·Filtration capacity and required dryness of the cake.

·Material of construction, such as SS304 or PP for corrosion resistance.

·Automation level, depending on plant size and labor capacity.

·Maintenance access and spare-part availability.

A well-chosen press ensures consistent operation, lower costs, and regulatory compliance for years to come.

7. Contribution to Sustainable Water Management

Beyond efficiency, a Hydraulic Filter Press supports global sustainability goals.

By maximizing water reuse and minimizing waste, it helps companies reduce their environmental footprint while meeting zero-liquid-discharge (ZLD) objectives.

It is both a technical and ecological investment—delivering long-term value to industries committed to responsible manufacturing.

Conclusion: A Proven Technology for the Future of Wastewater Treatment

The Hydraulic Filter Press remains one of the most efficient and reliable solutions for industrial wastewater dewatering. Its strong mechanical structure, high separation efficiency, and low operational costs make it indispensable in modern plants.

Partnering with a reputable China supplier that offers bulk-manufactured hydraulic filter presses provides businesses with durable, scalable, and cost-effective equipment—ensuring smooth operations and compliance with global environmental standards.

In a world striving for cleaner production and smarter water use, the hydraulic filter press is not just a piece of machinery—it is the foundation of sustainable industrial progress.

References

GB/T 7714:Soroushian F, Shang Y, Whitman E J, et al. Biosolids and Manure Dewatering With a Hydraulic De-juicing Press[C]//Residuals and Biosolids Conference 2006. Water Environment Federation, 2006: 1169-1173.

MLA:Soroushian, Fred, et al. "Biosolids and Manure Dewatering With a Hydraulic De-juicing Press." Residuals and Biosolids Conference 2006. Water Environment Federation, 2006.

APA:Soroushian, F., Shang, Y., Whitman, E. J., & Roxburgh, R. (2006, January). Biosolids and Manure Dewatering With a Hydraulic De-juicing Press. In Residuals and Biosolids Conference 2006 (pp. 1169-1173). Water Environment Federation.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province