NewsDetails

Hydraulic Filter Press Maintenance: Best Practices for Efficiency

author:Shuangcheng time:2025-10-28 00:24:18 Click:132

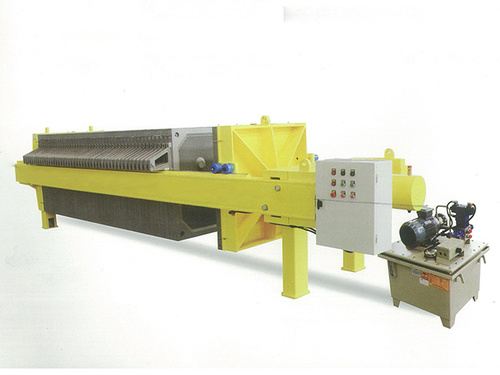

Industrial filtration systems depend on precision and consistency—and at the core of many setups lies the Hydraulic Filter Press. Whether used in wastewater treatment, chemical processing, or mining applications, this system is a workhorse of solid-liquid separation. However, even the most advanced filter press will underperform without a strong maintenance routine.

Proper Hydraulic Filter Press maintenance not only ensures continuous operation but also minimizes equipment fatigue and extends component lifespan. Partnering with a trusted China manufacturer that offers bulk supply capability provides long-term reliability and easier parts management for large-scale operations.

1. Why Hydraulic Filter Press Maintenance Is Critical

Over time, every mechanical system experiences wear—especially under continuous pressure cycles. Hydraulic filter presses handle immense stress as they compress filter cakes and sustain pressure across multiple plates.

Routine maintenance is crucial to:

·Maintain filtration throughput and pressure stability.

·Prevent costly downtime due to seal or plate failure.

·Extend hydraulic component and filter cloth life.

·Preserve operational safety standards and efficiency.

Ignoring scheduled maintenance leads to unbalanced pressure, hydraulic leaks, and reduced filtration quality.

2. Daily Checks for Optimal Operation

Before each production shift, operators should conduct a systematic review of the press’s hydraulic and mechanical components.

Daily inspection points include:

·Hydraulic oil level and cleanliness: Replace if murky or contaminated.

·System pressure: Verify against manufacturer’s specifications.

·Filter cloth condition: Remove accumulated solids and inspect for damage.

·Plate alignment: Misalignment causes uneven wear and poor sealing.

·Hydraulic cylinder condition: Look for oil leakage or sluggish movement.

A consistent inspection habit keeps your Hydraulic Filter Press maintenance program proactive rather than corrective.

3. Scheduled Maintenance: Weekly and Monthly Routines

Regular preventive maintenance is the backbone of long-term performance.

Weekly Tasks

·Clean the frame and plate surfaces: Avoid chemical deposits and sludge buildup.

·Lubricate moving joints: Use manufacturer-approved lubricants on sliding components.

·Drain and clean pipelines: Prevent sediment accumulation in feed lines.

Monthly Tasks

·Check hydraulic pumps and valves: Test response time and pressure stability.

·Inspect electrical controls: Ensure limit switches and sensors function correctly.

·Examine filter plates for deformation: Replace any warped or cracked plates immediately.

Such structured maintenance schedules ensure stable hydraulic performance and uniform filtration cycles .

4. Common Maintenance Errors to Avoid

Even skilled technicians can inadvertently shorten equipment life through improper practices. Avoid these common mistakes:

·Over-tightening bolts: Can crack filter plates and cause uneven sealing.

·Neglecting oil changes: Contaminated oil damages seals and valves.

·Skipping cloth cleaning: Clogged cloths reduce flow and filtration quality.

·Using non-recommended spare parts: Inferior components lower pressure retention and durability.

Following manufacturer-recommended service intervals keeps your system performing as designed.

5. Maximizing Component Lifespan

Durability depends heavily on part quality. Plates, cloths, and seals are all subject to high hydraulic stress and chemical exposure.

Key tips for extending component life:

·Use high-density polypropylene or stainless-steel filter plates for corrosion resistance.

·Select hydraulic seals with chemical and temperature tolerance.

·Opt for woven filter cloths designed for the specific slurry type.

Professional China manufacturers provide standardized spare parts through bulk supply channels, ensuring replacement consistency and reducing procurement lead times .

6. Cleaning and Storage for Longevity

Effective cleaning after each filtration cycle prevents material buildup and corrosion.

Best practices include:

1.Release system pressure and shut down all hydraulic circuits.

2.Remove filter cakes completely, using gentle scrapers.

3.Wash plates and cloths with clean water or mild detergent.

4.Dry components fully before storage.

5.Store in a clean, ventilated space away from moisture and corrosive chemicals.

This process keeps the press ready for immediate reactivation and prevents damage during downtime.

7. Partnering with a Reliable China Manufacturer

For industries operating multiple filtration lines, sourcing from a China manufacturer with bulk supply capacity ensures both scalability and consistency. Such suppliers often provide:

·Custom hydraulic systems adapted to local process conditions.

·Mass-produced spare parts with strict dimensional control.

·Technical support and maintenance training services.

Choosing a qualified manufacturer ensures long-term stability, standardized quality, and simplified logistics—especially for international operations requiring ongoing spare part supply.

Conclusion

A well-maintained Hydraulic Filter Press is an asset that drives operational reliability, safety, and productivity. Implementing structured inspection routines, avoiding common pitfalls, and sourcing components from a verified China manufacturer with bulk supply assurance can dramatically reduce downtime and improve system longevity.

In the world of industrial filtration, Hydraulic Filter Press maintenance isn’t an expense—it’s an investment in consistent performance and sustainable production.

References

GB/T 7714:Makansi F, Schmitz K. Data-driven condition monitoring of a hydraulic press using supervised learning and neural networks[J]. Energies, 2022, 15(17): 6217.

MLA:Makansi, Faried, and Katharina Schmitz. "Data-driven condition monitoring of a hydraulic press using supervised learning and neural networks." Energies 15.17 (2022): 6217.

APA:Makansi, F., & Schmitz, K. (2022). Data-driven condition monitoring of a hydraulic press using supervised learning and neural networks. Energies, 15(17), 6217.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province