NewsDetails

Hydraulic Filter Press Systems: Transforming Food Industry Filtration

author:Shuangcheng time:2025-10-21 20:38:16 Click:81

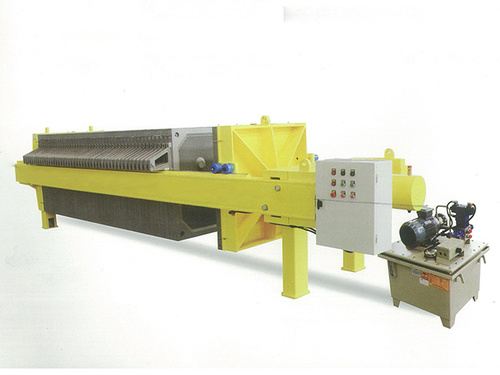

In today’s competitive food processing environment, manufacturers seek efficient ways to separate solids from liquids while maintaining product integrity. Hydraulic Filter Press systems have become essential in achieving high-quality filtration, reducing waste, and optimizing production processes.

These systems use controlled hydraulic pressure to separate liquid from solid matter, producing compact filter cakes and clear filtrate suitable for reuse. Many China suppliers and China manufacturers now offer bulk supply of hydraulic filter presses with tailored designs for specific food production requirements.

How Hydraulic Filter Press Technology Works

A Hydraulic Filter Press consists of multiple filter plates arranged in a frame and lined with food-grade cloths. Slurry or semi-liquid food products are pumped into the chambers between plates. Once full, hydraulic rams exert even pressure, forcing liquid through the filter cloth while retaining solids in a dense cake.

This process produces:

·Clear filtrate, which can be reused in cleaning, washing, or other production stages;

·Compact filter cakes, easier to transport, package, or process further.

Unlike traditional filtration, hydraulic systems ensure uniform pressure across all plates, yielding consistent results—a crucial factor in food production, where both safety and product quality are paramount.

Primary Advantages in Food Processing

1.Consistent Product Quality

By effectively removing fine solids and impurities, hydraulic filtration helps maintain uniform product characteristics across batches.

2.Higher Throughput

Hydraulic systems reduce cycle times compared to gravity or vacuum filtration, enabling faster production without compromising quality.

3.Water and Resource Conservation

Filtrate recovered during processing can be reused, cutting water consumption and lowering operating costs.

4.Compact and Modular Design

Hydraulic filter presses can be integrated into existing production lines even where floor space is limited.

5.Automation and Labor Efficiency

Many modern units include PLC controls, automatic plate shifting, and cake discharge systems, minimizing manual work and improving safety.

6.Flexible Customization

From fruit pulps to dairy whey and edible oils, presses can be adapted with different plate materials, sizes, and filtration media to meet various product requirements.

Applications Across Various Food Sectors

Juices and Beverages: Efficiently clarifies fruit and vegetable juices, wine, and other beverages, removing fine pulp while maintaining flavor and color.

Dairy Processing: Improves the quality of milk, whey, and yogurt by removing residual solids, extending shelf life, and reducing spoilage.

Edible Oils: Clarifies vegetable oils and animal fats, ensuring purity for bottling and further processing.

Sugar and Sweeteners: Filters sugar syrups, enhancing crystallization and final product consistency.

Sauces and Condiments: Stabilizes sauces and pastes, improving texture, color, and visual appeal.

Effective Maintenance for Longevity

Maintaining a Hydraulic Filter Press ensures optimal performance and extended service life:

·Regularly inspect hydraulic cylinders and hoses for leaks;

·Clean and replace filter cloths to maintain filtration efficiency;

·Check plate alignment for uniform pressure;

·Monitor automation systems to prevent cycle errors;

·Sanitize all contact surfaces according to food safety regulations.

Routine upkeep reduces downtime, enhances product consistency, and ensures hygienic processing standards.

Partnering with Trusted China Hydraulic Filter Press Manufacturers

Working with a reliable China manufacturer provides access to high-quality hydraulic filter presses suitable for industrial food production. Advantages include:

·Bulk supply at factory-direct pricing;

·Customizable configurations for different food products and production scales;

·Technical support, including installation, training, and spare parts;

·Fast delivery supported by established manufacturing and export systems.

China’s hydraulic filtration industry has matured, offering energy-efficient, reliable systems that meet international food safety standards.

Conclusion: Sustainable and Efficient Food Processing

A Hydraulic Filter Press is a critical investment for modern food processors. It improves product clarity, reduces waste, recycles process water, and enhances overall efficiency.

By sourcing directly from a dependable China supplier or China manufacturer, food production facilities can secure bulk supply, customized solutions, and reliable technical support.

Adopting hydraulic filtration technology represents not only an operational upgrade but also a commitment to sustainable, high-quality, and efficient food manufacturing.

References

GB/T 7714:De Paepe D, Coudijzer K, Noten B, et al. A comparative study between spiral-filter press and belt press implemented in a cloudy apple juice production process[J]. Food Chemistry, 2015, 173: 986-996.

MLA:De Paepe, Domien, et al. "A comparative study between spiral-filter press and belt press implemented in a cloudy apple juice production process." Food Chemistry 173 (2015): 986-996.

APA:De Paepe, D., Coudijzer, K., Noten, B., Valkenborg, D., Servaes, K., De Loose, M., ... & Van Droogenbroeck, B. (2015). A comparative study between spiral-filter press and belt press implemented in a cloudy apple juice production process. Food Chemistry, 173, 986-996.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province