NewsDetails

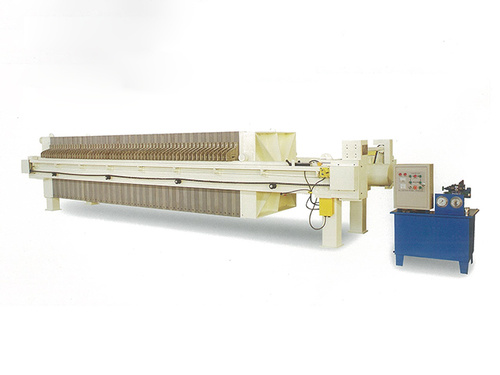

Understanding the Structural Design of a Chamber Filter Press

author:Shuangcheng time:2025-12-03 08:10:19 Click:97

As a manufacturer with reliable production capacity and stable bulk supply, we know that the structural design of a Chamber Filter Press determines how effectively it performs in demanding industrial filtration tasks. From wastewater treatment plants to chemical processing lines, the internal architecture of the equipment directly influences cake dryness, throughput, energy use, and service life.

The Chamber Filter Press has become a preferred solution across global industries because its design integrates durability, pressure resistance, and consistent chamber formation. To better understand its efficiency, it is important to examine its main structural components and how they contribute to high-quality filtration.

Why Structural Engineering Matters

In filtration equipment, structure controls performance.

The architecture of a Chamber Filter Press affects:

·Operating pressure capability

·Reliability during continuous cycles

·Filtrate clarity and cake uniformity

·Maintenance frequency

·Compatibility with diverse slurries

In short, the equipment’s structure is the foundation of its filtration precision.

Key Structural Components of a Chamber Filter Press

Each part of the system has a defined role. When combined, they form a high-pressure, leak-tight, and stable filtration environment.

1. Main Support Frame

The frame is the backbone of the entire press. It typically includes:

·A fixed head

·A moving head

·Sidebars or overhead beams

·Supporting legs and base components

·A hydraulic cylinder for plate compression

This structure absorbs the mechanical forces generated during pressing cycles and keeps plates properly aligned.

Structural significance:

·Provides long-term stability

·Ensures reliable sealing between plates

·Withstands repeated compression at high pressures

·Prevents frame deformation during continuous operation

A rigid and precision-machined frame is essential for safe, long-lasting filtration performance.

2. Chamber Filter Plates

Unlike plate-and-frame presses, the chamber plates contain molded recesses. When two plates are pressed together, the cavities form uniform filtration chambers.

·Typical plate materials include:

·Polypropylene (most common)

·Stainless steel (for corrosive or high-temperature slurries)

Cast iron (for heavy-duty applications)

Functional contributions:

·Create consistent chamber depth

·Hold filter cloths securely

·Support high mechanical pressure loads

·Produce uniform and dry filter cakes

These recessed plates are key to the Chamber Filter Press’s efficiency because they enable stable cake formation with minimal operator intervention.

3. Filter Cloth Layer

The filter cloth is the actual medium that separates solids from liquids. Cloth quality significantly influences:

·Filtrate clarity

·Cake permeability

·Resistance to blockage

·Filtration speed

Industries choose cloth fibers based on slurry characteristics. Common options include:

·Polypropylene

·Polyester

·Nylon

·Cotton

Why it matters:

Proper cloth selection and tensioning reduce leakage, optimize flow, and extend operational uptime.

4. Hydraulic Compression System

Hydraulics apply the force needed to press plates together and maintain a stable filtration chamber.

·A typical hydraulic system includes:

·A hydraulic pump

·Oil reservoir

·Cylinder assembly

·Pressure control components

·Safety valves

Advantages of reliable hydraulics:

·Ensures tight sealing between plates

·Prevents plate misalignment

·Maintains consistent operating pressure

·Supports safe and automatic plate clamping

Without a dependable hydraulic system, the entire press cannot maintain the chamber pressure required for effective separation.

5. Filtrate Discharge Channels

Within the plates, internal channels guide the filtered liquid out of the chamber.

Common discharge configurations:

·Open discharge – filtrate exits visibly from spouts

·Closed discharge – filtrate is enclosed for clean environments

·Top or bottom manifolds depending on process layout

These channels guarantee orderly filtrate flow and help avoid cross-contamination.

How Structural Design Enhances Filtration Performance

1. Uniform Pressure Distribution

The chamber architecture maintains equal pressure throughout the plate stack, resulting in predictable and consistent cake formation.

2. Efficient Filtration Pathway

Recessed plates channel slurry through controlled pathways, minimizing turbulence and improving filtration speed.

3. High-Dryness Filter Cakes

The design supports high dewatering pressure, reducing moisture content and facilitating easier cake discharge.

4. Long Equipment Lifespan

Well-engineered frames and plates reduce mechanical stress, extending operational life and lowering maintenance costs.

5. More Stable Operation

With fewer moving components than other filtration systems, Chamber Filter Presses operate with minimal vibration and high operational reliability.

Industries That Benefit from Chamber Filter Press Design

The structure makes it suitable for numerous applications, such as:

·Mining and mineral slurry separation

·Municipal and industrial wastewater treatment

·Chemical and petrochemical processing

·Metallurgy

·Food and beverage production

·Pharmaceutical and biotech filtration

Its capacity to handle high pressure, abrasive slurries, and continuous workloads makes it indispensable in these sectors.

Maintenance Linked to Structural Elements

A well-maintained structure ensures stable filtration:

✔ Clean plate surfaces regularly

Residue or dried cake can prevent effective sealing.

✔ Inspect plates for cracks or deformation

Especially when processing abrasive or high-pressure slurries.

✔ Replace filter cloths when worn

Cloth performance directly influences cake quality and filtrate clarity.

✔ Check hydraulic oil and sealing components

A decline in hydraulic performance reduces chamber stability.

Conclusion

The structural design of a Chamber Filter Press is engineered to maximize efficiency, durability, and precision in industrial filtration. Its frame, recessed chamber plates, filter cloths, hydraulics, and discharge channels work together to create a reliable and high-performing filtration system.

Backed by strong manufacturer-level production capabilities and consistent bulk supply, the Chamber Filter Press continues to be a trusted solution for industries seeking dependable solid–liquid separation with long-term operational value.

References

GB/T 7714:Rushton A, Ward A S, Holdich R G. Solid-liquid filtration and separation technology[M]. John Wiley & Sons, 2008.

MLA:Rushton, Albert, Anthony S. Ward, and Richard G. Holdich. Solid-liquid filtration and separation technology. John Wiley & Sons, 2008.

APA:Rushton, A., Ward, A. S., & Holdich, R. G. (2008). Solid-liquid filtration and separation technology. John Wiley & Sons.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province