NewsDetails

Chamber Filter Press Buying Guide: What Every Business Should Know

author:Shuangcheng time:2025-09-27 15:02:52 Click:157

Why Chamber Filter Presses Remain Essential

In many process-driven industries—such as mining, wastewater treatment, chemicals, and food production—efficient solid-liquid separation is the backbone of productivity. Among the available technologies, the Chamber Filter Press stands out for its ability to deliver dry filter cakes, reduce disposal costs, and operate with remarkable reliability.

If your business is planning to expand capacity or upgrade outdated equipment, understanding how to choose the right chamber filter press is crucial. This guide highlights the working principles, benefits, and critical buying considerations, while also showing why selecting a China manufacturer with proven bulk supply capability is a smart investment.

What Is a Chamber Filter Press?

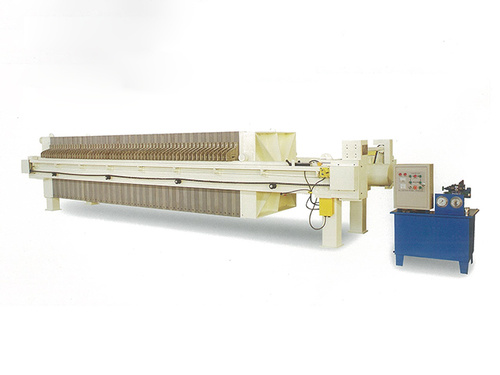

A Chamber Filter Press is a piece of industrial equipment designed to separate solids from liquids by using recessed plates lined with filter cloth. When slurry is pumped into the chambers, high pressure forces the liquid through the filter cloth, leaving behind compact solid cakes.

Main Advantages:

·High filtration efficiency with reduced moisture in filter cakes.

·Lower operating costs compared to alternative systems.

·Strong adaptability across diverse industries and applications.

·Durable design with a long service life and minimal maintenance needs.

·Customizable options in plate size, material, and automation features.

Why Businesses Choose Chamber Filter Press Technology

Compared with centrifuges or vacuum belt filters, the chamber filter press remains popular for several reasons:

·Operational stability with consistent performance.

·Cost efficiency, consuming less energy and requiring fewer consumables.

·Flexible scalability for both small-scale operations and large industrial plants.

·Automation compatibility, reducing labor intensity and improving process control.

For companies that value dependable performance and measurable cost savings, the chamber filter press continues to be the preferred solution.

Key Factors to Consider Before Purchasing

1. Capacity Needs

Match the equipment’s filtration volume to your daily production. Undersized models cause bottlenecks, while oversized units increase unnecessary costs.

2. Plate Materials and Sizes

Polypropylene plates: Lightweight, corrosion-resistant, suitable for most industries.

Cast iron plates: Extra durability for abrasive or high-temperature environments.

3. Filter Cloth Options

Cloth type affects cake dryness, filtration speed, and overall cloth life. Choose based on slurry characteristics.

4. Automation Features

Consider hydraulic closing systems, plate shifters, and PLC controls to boost efficiency and reduce manual intervention.

5. Supplier Reliability

A credible supplier should not only provide equipment but also spare parts, technical support, and customization. Working with a China manufacturer capable of bulk supply demonstrates production strength and ensures supply consistency.

Why Source from China Manufacturers

China has become a global hub for chamber filter press production, and for good reasons:

·Competitive pricing while maintaining quality standards.

·Mass production capacity to meet bulk supply demands.

·Export experience with compliance to international certifications.

·Flexible customization for industry-specific applications.

For buyers worldwide, partnering with an experienced China manufacturer ensures reliable delivery, tailored solutions, and sustainable cost advantages.

Common Buying Mistakes to Avoid

·Focusing only on upfront price without considering lifecycle costs.

·Overlooking after-sales support such as spare parts availability.

·Failing to verify supplier credibility and production scale.

·Selecting unsuitable plate or cloth materials, leading to inefficiency.

How to Ensure a Smart Investment

1.Define your processing requirements clearly.

2.Request technical drawings and specifications from multiple suppliers.

3.Ask for case studies or references from existing clients.

4.Verify certifications such as ISO or CE compliance.

5.Negotiate long-term bulk supply arrangements with a reliable China manufacturer.

Conclusion: Invest Wisely in Your Chamber Filter Press

The Chamber Filter Press continues to be one of the most effective solutions for solid-liquid separation, offering efficiency, durability, and scalability. By carefully assessing capacity, materials, and automation needs, businesses can make a confident decision.

Above all, sourcing from a proven China manufacturer with bulk supply capabilities ensures consistent quality and long-term reliability. For companies focused on productivity and cost savings, this is the pathway to sustainable growth.

References

GB/T 7714:Teutscher D, Weber-Carstanjen T, Simonis S, et al. Predicting Filter Medium Performances in Chamber Filter Presses with Digital Twins Using Neural Network Technologies[J]. Applied Sciences, 2025, 15(9): 4933.

MLA:Teutscher, Dennis, et al. "Predicting Filter Medium Performances in Chamber Filter Presses with Digital Twins Using Neural Network Technologies." Applied Sciences 15.9 (2025): 4933.

APA:Teutscher, D., Weber-Carstanjen, T., Simonis, S., & Krause, M. J. (2025). Predicting Filter Medium Performances in Chamber Filter Presses with Digital Twins Using Neural Network Technologies. Applied Sciences, 15(9), 4933.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province