NewsDetails

Chamber Filter Press Efficiency in Mining and Wastewater Treatment

author:Shuangcheng time:2025-09-24 11:17:06 Click:139

Why Filtration Efficiency Matters

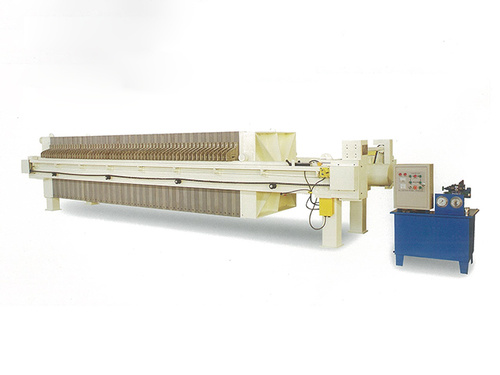

Across industries such as mining and wastewater treatment, efficient separation of solids and liquids is critical for reducing costs and meeting environmental requirements. The Chamber Filter Press has become a dependable tool in achieving these goals. Its strong design, ability to produce dry filter cakes, and adaptability across different slurry types make it a preferred solution worldwide.

Today, many facility managers secure their equipment from a China supplier or China factory, taking advantage of bulk supply options that balance affordability with consistent quality.

The Operating Principle of Chamber Filter Press

At its core, the Chamber Filter Press relies on pressure to separate liquid from solids. Slurry is pumped into chambers, where liquid exits through filter cloths, leaving solid cakes behind. The results include:

·Efficient moisture removal for reduced disposal costs

·High solid recovery for better resource utilization

·Reliable cycle performance for consistent output

This simplicity combined with effectiveness is why the Chamber Filter Press continues to play a vital role in heavy industries.

Mining Applications: Better Recovery and Reduced Waste

In mining operations, waste handling and mineral recovery determine profitability. Using a Chamber Filter Press provides:

·Improved mineral yield: Drier cakes retain less valuable material.

·Environmental responsibility: Cleaner water discharge protects ecosystems.

·Lower logistics costs: Reduced waste volume cuts transport expenses.

By choosing bulk equipment supply from a China factory, mining operators ensure dependable capacity and lower procurement risks.

Wastewater Treatment: Cleaner Outputs, Lower Overheads

Treatment plants in both municipal and industrial sectors benefit from Chamber Filter Press systems because they:

·Deliver clearer effluent ready for recycling or discharge

·Help meet strict regulatory standards

·Decrease sludge volumes, reducing long-term handling costs

This balance of compliance and cost savings explains why the Chamber Filter Press remains widely adopted in wastewater treatment facilities worldwide.

Distinct Advantages Over Alternative Systems

Compared with centrifuges, belt filters, or other methods, the Chamber Filter Press provides:

1.Energy savings due to lower power demand

2.Adaptability for various slurry types

3.Longevity when maintained properly

4.Custom scalability for both small and large operations

Such benefits make it not just a traditional system but a forward-looking solution for modern industries.

Why Industries Prefer China Suppliers

China has become a global hub for Chamber Filter Press manufacturing. Companies sourcing directly from a China supplier gain:

·Bulk supply with competitive pricing

·High-volume production to support large projects

·Customization options that fit project-specific needs

·Compliance with international certifications like ISO and CE

For many businesses, partnering with a China factory ensures predictable costs and steady supply chains.

Maintaining Long-Term Performance

For continuous efficiency, facilities should:

·Replace filter cloths when worn

·Keep hydraulic systems regularly serviced

·Upgrade automation controls when available

·Use original spare parts from trusted suppliers

Following these practices guarantees the Chamber Filter Press remains reliable for years.

Conclusion: Dependable Efficiency for Key Industries

The Chamber Filter Press stands out as a cornerstone in both mining and wastewater treatment. Its ability to reduce costs, improve water quality, and recover valuable solids makes it indispensable.

Sourcing from China suppliers and factories offering bulk supply further strengthens its position as the go-to solution, providing industries with affordable, efficient, and globally compliant equipment.

In short, investing in a Chamber Filter Press today is a long-term strategy for operational excellence and sustainable growth.

References

GB/T 7714:Amuda O S, Amoo I A. Coagulation/flocculation process and sludge conditioning in beverage industrial wastewater treatment[J]. Journal of Hazardous Materials, 2007, 141(3): 778-783.

MLA:Amuda, O. S., and I. A. Amoo. "Coagulation/flocculation process and sludge conditioning in beverage industrial wastewater treatment." Journal of Hazardous Materials 141.3 (2007): 778-783.

APA:Amuda, O. S., & Amoo, I. A. (2007). Coagulation/flocculation process and sludge conditioning in beverage industrial wastewater treatment. Journal of Hazardous Materials, 141(3), 778-783.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province