NewsDetails

How a Hydraulic Filter Press Works: Step-by-Step Process

author:Shuangcheng time:2025-10-06 16:17:50 Click:165

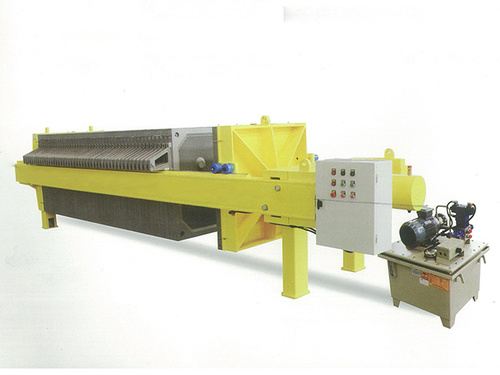

For industries that rely on efficient solid-liquid separation, the Hydraulic Filter Press stands out as one of the most trusted technologies. Its design—combining hydraulic power with precision-engineered filter plates—delivers cleaner filtrates and drier solids than many other methods.

Used widely in mining, wastewater treatment, food processing, and chemicals, this equipment has become a cornerstone of industrial filtration. For businesses sourcing equipment internationally, China suppliers and China manufacturers with bulk supply capabilities are reliable partners to support expansion.

Step 1: Slurry Intake

The cycle begins when slurry, a mixture of solids suspended in liquid, is pumped into the filter press. Hydraulic pressure keeps the filter plates tightly sealed, preventing leaks while filling the chambers.

Step 2: Pressure Filtration

Once the chambers are filled, the hydraulic system increases pressure. This force drives liquid through the filter cloth, leaving solids trapped inside the chamber. The filtrate exits through discharge outlets, while solids begin to build up.

Step 3: Cake Consolidation

As filtration continues, the retained solids compact into dense “filter cakes.” The applied hydraulic pressure ensures reduced moisture levels, making the cakes easier to handle and dispose of. This stage is critical for industries seeking maximum efficiency.

Step 4: Cake Drying (Optional)

For certain processes, an additional washing or drying step may be included. Compressed air or water can pass through the cakes, removing residual liquid and increasing product purity.

Step 5: Plate Separation and Cake Release

When the filtration cycle is complete, the system automatically releases hydraulic pressure. The plates then move apart, allowing the filter cakes to drop out. Depending on the design, this step may be fully automated or semi-automatic.

Step 6: Preparation for the Next Cycle

After cake discharge, the cloths and plates may require cleaning. Once reset, the press is ready for the next filtration cycle. This repetitive process ensures continuous productivity in industrial settings.

Applications Across Industries

The adaptability of the Hydraulic Filter Press makes it suitable for:

·Mining & Metallurgy: Processing concentrates and tailings.

·Food & Beverage: Clarifying wine, juice, and edible oils.

·Chemicals & Pharmaceuticals: Managing fine particles or corrosive slurries.

·Municipal Wastewater: Dewatering sludge to reduce handling costs.

·Industrial Effluents: Treating liquid waste streams before discharge.

Advantages of Hydraulic Filter Press

Businesses prefer the Hydraulic Filter Press because it offers:

·Superior dryness of solids compared with many alternatives.

·Reduced energy costs through efficient hydraulic systems.

·Durable build with long service life.

·Configurable options for different industries.

·Automation choices for reduced labor requirements.

These strengths explain why many global buyers rely on China manufacturers and China suppliers with bulk supply to meet industrial demands.

Choosing the Right Hydraulic Filter Press

When purchasing, keep in mind:

·Size and volume of the chambers.

·Plate material compatibility (polypropylene, stainless steel, etc.).

·Stability and safety of the hydraulic unit.

·Maintenance and ease of cloth replacement.

·Supplier reliability, training, and after-sales support.

Maintenance Recommendations

To ensure long-term performance:

·Inspect and service hydraulic pumps and seals.

·Replace filter cloths regularly.

·Keep slurry feed consistent to avoid uneven cake formation.

·Clean plates after each cycle.

·Lubricate moving components.

Why Work With China Manufacturers?

Partnering with China suppliers or China manufacturers offers clear advantages:

·Bulk supply capacity, ensuring multiple units and spare parts are available.

·Competitive cost structures, making equipment more affordable.

·Customization, with tailored designs to match specific industrial needs.

These benefits make sourcing from China a practical choice for businesses scaling operations.

Conclusion

The Hydraulic Filter Press follows a simple yet powerful cycle: slurry feeding, pressure filtration, cake formation, optional drying, and cake discharge. This repeatable process delivers consistent results across multiple industries.

For buyers planning long-term investment, partnering with China manufacturers and China suppliers capable of bulk supply ensures reliable quality and scalability. Unlike other systems, the Hydraulic Filter Press continues to prove itself as a valuable, durable, and cost-efficient solution in industrial filtration.

References

GB/T 7714:Köry J, Krupp A U, Please C P, et al. The effect of compressibility on the behaviour of filter media[J]. IMA Journal of Applied Mathematics, 2020, 85(4): 564-583.

MLA:Köry, Jakub, et al. "The effect of compressibility on the behaviour of filter media." IMA Journal of Applied Mathematics 85.4 (2020): 564-583.

APA:Köry, J., Krupp, A. U., Please, C. P., & Griffiths, I. M. (2020). The effect of compressibility on the behaviour of filter media. IMA Journal of Applied Mathematics, 85(4), 564-583.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province