NewsDetails

How to Maintain a Chamber Filter Press for Durability

author:Shuangcheng time:2025-09-14 22:14:58 Click:199

Why Proper Care Extends Chamber Filter Press Longevity

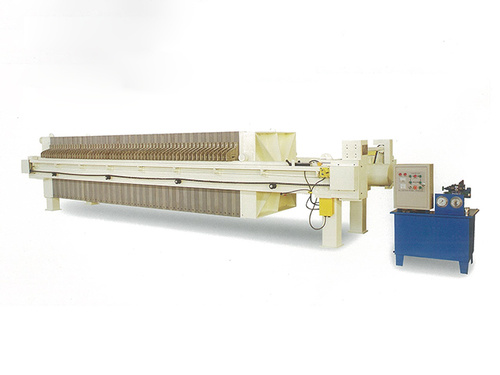

The Chamber Filter Press has become one of the most dependable machines in solid-liquid separation processes. From mining and chemical plants to wastewater treatment and food production, its ability to deliver drier cakes and reduce waste handling costs makes it a vital tool.

Yet, like any industrial equipment, longevity and efficiency depend on consistent upkeep. Regular maintenance not only avoids costly downtime but also ensures the press continues to perform at peak levels. For companies sourcing from China suppliers or Chinese manufacturers, especially those offering bulk supply, these practices guarantee that their investment produces maximum returns over time.

Daily Care for Consistent Efficiency

1. Maintain Filter Cloth Cleanliness

Filter cloths are central to separation quality. After each cycle, they should be washed to prevent clogging and to keep filtration speed steady. Worn cloths should be swapped out promptly to avoid reduced throughput.

2. Keep the Hydraulic System Healthy

The hydraulic unit generates the pressure needed to keep plates tightly closed. Regularly checking oil levels, seals, and valves helps prevent energy loss and ensures reliable operation.

3. Align and Clean Plates Frequently

Residues left on plates can interfere with sealing, leading to leaks or uneven pressure distribution. Cleaning plates thoroughly and checking alignment after use avoids premature wear.

Preventive Maintenance for Long-Term Reliability

4. Lubricate Mechanical Components

Smooth operation of shifting devices and guide rods depends on proper lubrication. Applying grease at recommended intervals reduces wear and keeps movement precise.

5. Inspect Control and Electrical Systems

Automation enhances efficiency, but loose wires or faulty sensors can cause unexpected stoppages. Routine checks of panels and switches reduce risks of breakdowns.

6. Replace Aging Seals and Gaskets

Sealing elements wear naturally with pressure cycles. Replacing them at the first signs of deterioration avoids leakage and maintains filtration efficiency.

Best Practices for Maximizing Service Life

7. Respect Design Limits

Operating within capacity is critical. Overfeeding slurry or exceeding rated pressure shortens the lifespan of even the most durable press.

8. Schedule Professional Maintenance

Even when daily checks are done, technical inspections by specialists once or twice a year can identify hidden issues such as cracks or misalignment.

9. Control the Working Environment

Dust, humidity, and corrosive atmospheres accelerate damage. A clean, stable environment prolongs both mechanical and electrical component life.

10. Invest in Operator Training

Human error is often behind equipment failure. Well-trained staff can extend machine life by following safe and efficient operating procedures.

Benefits of Maintenance in Industrial Operations

Businesses that maintain their Chamber Filter Press properly enjoy:

·Lower Operating Expenses: Reduced energy and repair costs.

·Consistent Productivity: Reliable performance across cycles.

·Extended Lifespan: More years of effective operation from each unit.

·Sustainability Gains: Less waste, reduced environmental footprint.

Why Work with China Suppliers and Chinese Manufacturers

Partnering with China suppliers or Chinese manufacturers offers unique advantages, especially when bulk supply is required:

·Assurance of consistent delivery capacity.

·Lower pricing due to optimized production.

·Flexibility for custom design and capacity.

·Compliance with international standards such as ISO and CE.

Collaborating with suppliers that have strong production capacity ensures businesses receive not only high-quality equipment but also long-term technical support.

Conclusion: Chamber Filter Press as a Long-Term Investment

The Chamber Filter Press is built for durability and efficiency, but its performance depends on how well it is maintained. By implementing regular inspections, preventive care, and good operator practices, businesses can maximize service life and achieve better returns.

When purchased from experienced China suppliers or Chinese manufacturers with bulk supply capabilities, companies secure both reliable machinery and lasting support.

Maintaining a Chamber Filter Press today means protecting operational stability, reducing downtime, and ensuring profitability well into the future.

References

GB/T 7714:Morsch P, Arnold A, Schulze H, et al. In-situ cleaning process of chamber filter presses with sensor-controlled and demand-oriented automation[J]. Separation and Purification Technology, 2021, 256: 117793.

MLA:Morsch, Patrick, et al. "In-situ cleaning process of chamber filter presses with sensor-controlled and demand-oriented automation." Separation and Purification Technology 256 (2021): 117793.

APA:Morsch, P., Arnold, A., Schulze, H., Werner, R., Anlauf, H., Geier, D. U., ... & Nirschl, H. (2021). In-situ cleaning process of chamber filter presses with sensor-controlled and demand-oriented automation. Separation and Purification Technology, 256, 117793.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province