NewsDetails

How to Plan Capacity for Hydraulic Filter Press Systems

author:Shuangcheng time:2025-12-18 10:28:49 Click:178

Capacity Planning for a Hydraulic Filter Press

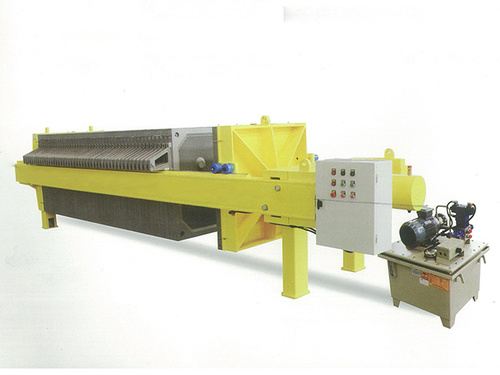

A Hydraulic Filter Press is a critical component in solid–liquid separation across industries such as wastewater treatment, mining, chemical processing, and food production. Selecting the correct capacity is essential for maintaining stable production, controlling operational costs, and meeting discharge or recycling requirements.

Capacity planning is more than choosing a machine size—it requires a systematic evaluation of process conditions, material characteristics, and long-term production goals. For operations working directly with equipment manufacturers or managing bulk supply for large projects, accurate capacity planning helps ensure reliable performance and scalability.

This article outlines the key principles, calculations, and practical considerations involved in planning capacity for a Hydraulic Filter Press system.

1. Understanding Hydraulic Filter Press Capacity

The capacity of a Hydraulic Filter Press refers to the amount of slurry it can process within a defined time period. This is influenced by several interacting factors rather than a single specification.

Key Capacity Indicators

·Filtration area (m²)

·Chamber volume (L)

·Cake thickness

·Cycle time (filtration, pressing, discharge)

Understanding how these elements interact is the foundation of effective system planning.

2. Analyze Slurry Characteristics First

Slurry properties directly determine filtration performance.

Key Slurry Parameters

·Solid concentration: Higher solids typically reduce filtration speed.

·Particle size distribution: Fine particles slow filtration and increase cake resistance.

·Viscosity: Affects flow rate and pressure requirements.

·Compressibility: Impacts achievable cake dryness.

Laboratory filtration tests are strongly recommended before finalizing capacity calculations.

3. Define Production Requirements Clearly

Before selecting a Hydraulic Filter Press, define your production targets.

Questions to Answer

·Required throughput per hour or per shift

·Operating hours per day

·Peak vs. average load conditions

·Allowable downtime for maintenance

For continuous production environments, planning capacity with a safety margin helps avoid bottlenecks during peak demand.

4. Filtration Cycle Time Considerations

Cycle time plays a major role in determining real-world capacity.

Cycle Stages

1.Slurry feeding

2.Pressure filtration

3.Cake squeezing (optional)

4.Cake discharge

5.Cloth washing (if required)

Reducing non-filtration time can significantly improve overall throughput without increasing equipment size.

5. Selecting Filtration Area and Plate Configuration

Filtration area is often the most visible specification, but it must align with slurry behavior.

Key Factors

·Plate size and number

·Chamber depth

·Cloth permeability

Increasing plate count increases capacity but also affects footprint and hydraulic closing force requirements. Manufacturer production guidelines often provide standard configurations to support scalable system design.

6. Hydraulic Pressure and Mechanical Limits

Hydraulic systems provide the closing force needed to maintain seal integrity during high-pressure filtration.

Important Considerations

·Maximum operating pressure

·Plate frame strength

·Safety margin for wear over time

Oversizing hydraulic pressure does not always improve capacity and may accelerate component wear.

7. Planning for Future Expansion

Capacity planning should consider future production growth.

Scalable Design Options

·Space for additional plates

·Modular plate expansion

·Hydraulic system upgrade compatibility

In many production facilities, initial capacity planning with expansion capability is more cost-effective than full replacement later.

8. Utility and Infrastructure Requirements

Supporting systems can limit effective capacity if not properly planned.

Infrastructure Factors

·Feed pump capacity

·Power supply stability

·Compressed air availability

·Filtrate handling and storage

A well-matched system ensures that the Hydraulic Filter Press operates at its designed efficiency.

9. Common Capacity Planning Mistakes

Avoiding these mistakes helps protect long-term performance:

·Selecting based on plate area alone

·Ignoring slurry variability

·Underestimating cycle downtime

·Failing to plan for peak loads

·Careful evaluation prevents frequent stoppages and performance losses.

Conclusion: Optimizing Hydraulic Filter Press Capacity

A Hydraulic Filter Press performs best when its capacity matches actual process demands. Effective planning requires analyzing slurry characteristics, defining production goals, optimizing cycle time, and considering future scalability. For operations sourcing equipment through bulk supply arrangements or working directly with manufacturers, a structured capacity planning approach ensures reliable operation, controlled costs, and consistent output.

By applying these principles, a Hydraulic Filter Press becomes a stable and efficient asset supporting long-term production performance and operational confidence.

References

GB/T 7714:Sutherland K S, Chase G. Filters and filtration handbook[M]. Elsevier, 2011.

MLA:Sutherland, Kenneth S., and George Chase. Filters and filtration handbook. Elsevier, 2011.

APA:Sutherland, K. S., & Chase, G. (2011). Filters and filtration handbook. Elsevier.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province