NewsDetails

Hydraulic Filter Press for Mining: Tailings and Concentrate Recovery

author:Shuangcheng time:2025-10-18 19:16:35 Click:180

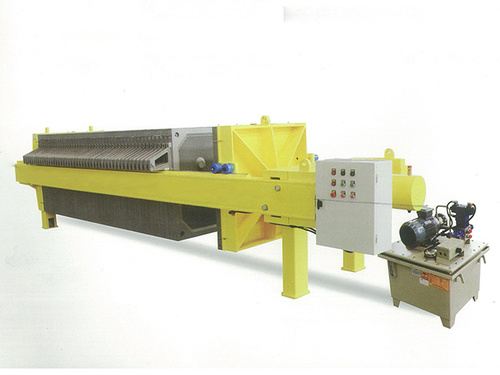

The mining industry continually seeks better methods to manage tailings and reclaim valuable minerals. One of the most efficient solutions available today is the Hydraulic Filter Press.

This system is engineered to handle high-volume slurry and perform solid–liquid separation with remarkable precision. By applying controlled hydraulic pressure, it separates water from mineral waste, producing dry, compact cakes and reusable filtrate.

Modern Hydraulic Filter Press units are widely adopted across mining sites for their ability to enhance water recovery, reduce environmental impact, and optimize production cycles. Many China manufacturers now specialize in producing these systems at scale, offering bulk supply and customized designs for different minerals and process requirements.

Understanding Hydraulic Filter Press Technology in Mining Operations

A Hydraulic Filter Press operates by channeling slurry into a set of filter plates lined with cloths. Once the chambers are filled, hydraulic rams apply pressure, forcing liquid through the filter medium and leaving behind solid residues.

The outcome is twofold:

·Clear filtrate that can be recycled into processing lines;

·Dense filter cakes that are easier to transport, store, or repurpose.

This method ensures efficient waste reduction and supports environmentally responsible tailings management. In mineral processing plants, hydraulic filtration is commonly applied for tailings dehydration, concentrate thickening, and sludge treatment.

Core Advantages of Hydraulic Filtration Systems

1.Higher Dewatering Efficiency

The use of hydraulic compression allows the system to extract more water from slurry compared with conventional thickening equipment.

2.Recycled Water Utilization

The filtrate generated can be reintegrated into the washing or flotation process, reducing freshwater consumption and operating costs.

3.Compact Structural Design

The compact frame of the Hydraulic Filter Press requires less floor space and integrates easily into existing process lines.

4.Low Energy Consumption & Automation

Modern models feature automatic plate shifting, filter cake release, and PLC control, making them energy-efficient and labor-saving.

5.Flexible for Multiple Ores

Whether processing gold, copper, or non-metallic minerals, the press can be customized with specific plate materials and chamber sizes.

Improving Tailings Handling and Mineral Recovery

Tailings management remains one of the biggest challenges in mining operations. Excess water and fine particles in waste streams can pose environmental and operational problems.

Using a Hydraulic Filter Press significantly improves this process. It extracts additional water from tailings, creating drier, stable material suitable for stacking or safe disposal. At the same time, valuable mineral fines that would otherwise be lost in slurry can be recovered through precise pressure filtration.

By incorporating this system into a plant’s processing chain, mines can enhance concentrate recovery rates and reduce reliance on costly water-treatment facilities. This not only saves resources but also supports eco-friendly mining initiatives.

Maintenance Practices to Ensure Long-Term Performance

Keeping a Hydraulic Filter Press in top working condition ensures consistent results over years of use. Here are several recommended maintenance steps:

·Check hydraulic cylinders and hoses regularly to prevent leaks.

·Replace worn filter cloths to maintain steady filtration quality.

·Clean discharge paths to avoid blockages and uneven pressure.

·Monitor control parameters such as cycle timing and pressure readings for smooth operation.

Routine inspection and proper cleaning help extend the lifespan of critical components and minimize downtime, ensuring your equipment remains productive across heavy-duty mining cycles.

Partnering with a Reliable China Hydraulic Filter Press Manufacturer

Collaborating with an established China manufacturer provides direct access to Hydraulic Filter Press units designed for industrial-scale mining. These suppliers often support bulk supply and offer fully tailored configurations, from plate materials to automation levels.

Advantages of sourcing directly from China include:

·Cost-effective production with consistent quality standards.

·Comprehensive engineering support for specific ore types.

·Quick parts availability and responsive after-sales assistance.

·Flexible customization to match unique process requirements.

China’s hydraulic filtration industry has evolved rapidly, with many suppliers now exporting advanced, energy-efficient systems worldwide. Their proven quality and scalability make them ideal partners for modern mining projects.

Conclusion: Smarter Mining Through Efficient Filtration

The Hydraulic Filter Press has redefined how mining operations handle waste and water recovery. By efficiently separating solids and liquids, it contributes to cleaner tailings, higher mineral yields, and lower operating costs.

Choosing a dependable China supplier or China manufacturer ensures not only superior build quality but also bulk production capacity and technical expertise suited to your site’s specific challenges.

Adopting this advanced filtration technology is a practical step toward more sustainable, productive, and responsible mining operations — where every drop and particle truly counts.

References

GB/T 7714:Fränkle B, Bragin G. What happens inside a filter press during tailings filtration[C]//Paste 2025: Proceedings of the 27th International Conference on Paste, Thickened and Filtered Tailings. Australian Centre for Geomechanics, 2025: 181-190.

MLA:Fränkle, Bernd, and Gleb Bragin. "What happens inside a filter press during tailings filtration." Paste 2025: Proceedings of the 27th International Conference on Paste, Thickened and Filtered Tailings. Australian Centre for Geomechanics, 2025.

APA:Fränkle, B., & Bragin, G. (2025, April). What happens inside a filter press during tailings filtration. In Paste 2025: Proceedings of the 27th International Conference on Paste, Thickened and Filtered Tailings (pp. 181-190). Australian Centre for Geomechanics.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province