NewsDetails

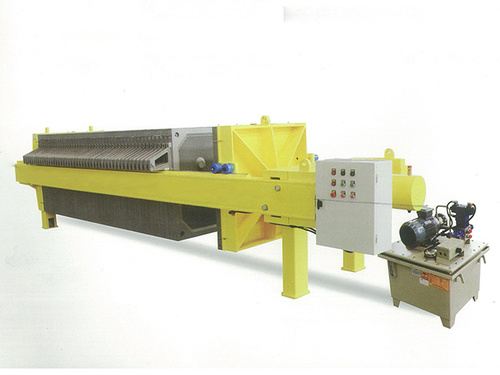

Hydraulic Filter Press Plate Design Explained

author:Shuangcheng time:2025-10-15 18:13:55 Click:128

In any filtration system, hydraulic filter press design determines both efficiency and durability. At the heart of this design are the plates, which form the filtration chambers where solids are separated from liquids. The way these plates are engineered directly influences cycle time, cake quality, and maintenance needs.

This article unpacks the essential aspects of filter press plate design, from material selection to structural variations, and explains why sourcing from China manufacturers with strong bulk supply capabilities helps industries secure consistent and cost-efficient equipment.

Why Plates Matter in Hydraulic Filter Press Design

Plates are not just structural parts—they define the performance of the press. Their design ensures slurry is evenly distributed, pressure is consistently applied, and leakage is minimized. A properly designed plate also helps maintain uniform cake thickness, which improves dryness and reduces operating costs over time.

Materials Commonly Used in Plate Design

The material composition of plates is critical for handling different slurries:

·Polypropylene (PP): Lightweight, corrosion-resistant, and ideal for industries requiring chemical resistance, such as food and chemical processing.

·Cast Iron: Extremely strong and long-lasting, often used in mining and heavy-duty filtration tasks.

·Stainless Steel: Favored in industries where hygiene and chemical durability are essential, such as pharmaceuticals and food production.

Choosing the right material ensures that plates remain effective and durable in demanding environments.

Plate Configurations and Their Functions

Different plate types offer flexibility across industries:

·Recessed Chamber Plates: Provide easy cake removal and reduce handling effort.

·Membrane Plates: Feature inflatable membranes to squeeze cakes further, producing lower moisture content.

·Plate and Frame Models: Traditional in design, but still valuable where very clear filtrate is required.

Each configuration impacts filtration speed, cake dryness, and overall system efficiency.

Key Factors in Hydraulic Filter Press Design

When selecting a hydraulic filter press, several design aspects should be assessed:

1.Pressure Range – Determines how dry the final cakes will be.

2.Cake Thickness – Influences drying time and disposal efficiency.

3.Chemical Resistance – Prevents damage to plates in corrosive applications.

4.Ease of Cleaning – Reduces downtime and simplifies maintenance.

These considerations help ensure that the filter press meets both production and cost-efficiency goals.

Industrial Applications of Filter Press Plates

Hydraulic filter press plates find use across a wide range of sectors, including:

·Mining and mineral processing.

·Municipal and industrial wastewater treatment.

·Food and beverage manufacturing.

·Pharmaceutical and chemical industries.

This versatility is possible because design variations allow adaptation to different slurry characteristics and production scales.

The Value of Working with China Manufacturers

For companies requiring dependable and cost-effective supply, China manufacturers remain a strategic choice. Many China suppliers demonstrate genuine bulk supply capacity, producing and delivering equipment at scale without compromising quality. This ability to handle large orders on time proves manufacturing strength and builds long-term trust with global buyers.

Conclusion

The effectiveness of a hydraulic filter press design depends heavily on the quality and structure of its plates. Well-chosen materials, thoughtful engineering, and the right plate type can significantly improve cake dryness, reduce downtime, and lower costs.

For industries that need consistent availability, sourcing from established China manufacturers with bulk supply capabilities ensures both affordability and reliability. Recognizing the importance of plate design in hydraulic filter presses is key to achieving sustainable and efficient filtration operations.

References

GB/T 7714:Stickland A D, de Kretser R G, Scales P J, et al. Numerical modelling of fixed-cavity plate-and-frame filtration: formulation, validation and optimisation[J]. Chemical Engineering Science, 2006, 61(12): 3818-3829.

MLA:Stickland, Anthony D., et al. "Numerical modelling of fixed-cavity plate-and-frame filtration: formulation, validation and optimisation." Chemical Engineering Science 61.12 (2006): 3818-3829.

APA:Stickland, A. D., de Kretser, R. G., Scales, P. J., Usher, S. P., Hillis, P., & Tillotson, M. R. (2006). Numerical modelling of fixed-cavity plate-and-frame filtration: formulation, validation and optimisation. Chemical Engineering Science, 61(12), 3818-3829.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province