NewsDetails

Industrial Applications of Filter Plates in Wastewater and Mining

author:Shuangcheng time:2025-11-12 05:42:06 Click:98

In modern industrial filtration, the Filter Plate has become an essential component for achieving reliable and efficient solid-liquid separation. Whether in wastewater treatment plants or large-scale mining operations, the performance of the filtration system depends heavily on the design and quality of its filter plates. As a China manufacturer providing bulk supply of industrial filter plates, we understand how precision engineering, material selection, and durability affect operational outcomes and cost efficiency.

1. The Role of Filter Plates in Industrial Filtration

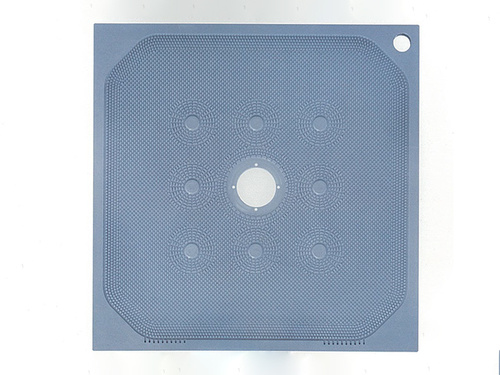

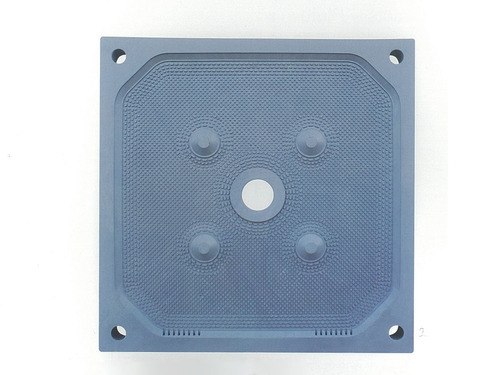

A filter plate serves as the backbone of a filter press, where slurry is pressed under pressure to separate solids from liquids. Each plate supports a filter cloth, forming a chamber that captures solids while filtrate passes through. The structure and surface design of the filter plate determine filtration rate, cake thickness, and dryness, which in turn influence productivity and energy consumption.

Unlike other filtration methods, a filter plate-based system provides a mechanical, chemical-free approach to separating materials. This makes it particularly suitable for heavy-duty industries like wastewater treatment and mineral processing, where large volumes of slurry must be handled efficiently.

2. Filter Plates in Wastewater Treatment

In wastewater treatment facilities, removing moisture from sludge is one of the most energy-intensive and costly steps. Filter plates play a key role in dewatering sludge to reduce its volume before disposal. Through high-pressure filtration, the plate structure allows water to pass through while trapping suspended solids, resulting in a compact, easy-to-handle cake.

The advantages of using advanced filter press plates in wastewater applications are significant. Polypropylene plates, for instance, are resistant to chemicals and corrosion, making them ideal for treating industrial effluents. They also offer a long service life, minimal maintenance, and consistent performance even under continuous operation.

Moreover, the use of hydraulic filter press systems with high-quality filter plates helps reduce the moisture content of sludge, minimizing transportation and landfill costs. Many treatment facilities now turn to China-made filter plates because of their reliability, affordability, and availability in large quantities for municipal and industrial projects.

3. Filter Plates in Mining and Mineral Processing

In mining operations, managing tailings and mineral concentrates efficiently is crucial for both environmental and economic reasons. Filter plates are widely used in the dewatering stage of ore processing, separating valuable minerals from water before refining or disposal.

During tailings filtration, these plates ensure that water can be recovered and reused, significantly lowering the operation’s water footprint. In concentrate filtration, the robust structure of the plates allows them to handle high pressure and abrasive materials without deformation. This not only extends equipment life but also improves the purity and dryness of the filtered cake.

Modern membrane filter plates have become increasingly popular in mining due to their ability to achieve lower residual moisture levels compared to conventional chamber plates. Reinforced polypropylene or composite materials further enhance their resistance to wear, making them suitable for heavy-duty mining environments.

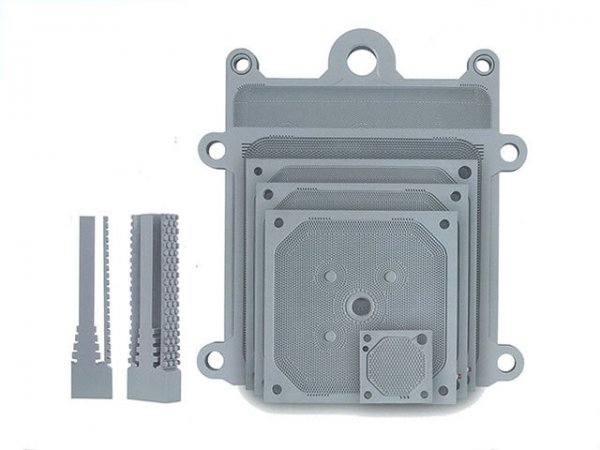

With decades of experience, Chinese filter plate manufacturers have developed advanced molding technologies and quality control systems to produce plates with exceptional flatness, sealing performance, and filtration stability. These innovations make them a preferred choice for international mining companies looking for reliable filtration components at competitive prices.

4. Key Considerations When Choosing a Filter Plate

Selecting the right filter plate depends on the nature of the slurry, desired moisture content, and process pressure. Polypropylene plates are the most common due to their lightweight design and chemical resistance, while stainless steel plates are used for high-temperature or corrosive processes.

For wastewater applications, chamber plates are usually sufficient, offering a balance of efficiency and durability. In contrast, mining operations benefit more from membrane plates that use additional compression to extract more liquid, resulting in drier cakes.

Pressure capacity is another important factor. While standard filter plates operate between 0.6 and 1.6 MPa, mining plates often require pressures of 2.0 MPa or higher. Ensuring proper plate selection not only enhances filtration efficiency but also reduces downtime and maintenance costs.

To meet diverse industrial demands, a China manufacturer capable of bulk supply can customize filter plate sizes, materials, and structural reinforcements to match specific process needs.

5. Advantages of Working with a China Manufacturer

Over the past decade, China has become one of the world’s leading suppliers of industrial filter plates, offering a combination of technological innovation, consistent quality, and cost efficiency. Manufacturers in China utilize advanced injection molding machines and strict testing standards to ensure dimensional accuracy and mechanical strength in every plate produced.

By sourcing directly from a China-based filter plate factory, buyers gain access to bulk production capacity, shorter delivery times, and flexible customization. Whether you require replacements for existing filter presses or full sets for new installations, working directly with a manufacturer eliminates intermediaries and ensures better technical support.

6. Future Development and Sustainability

The future of filtration technology is shifting toward sustainability and automation. Filter plates are now being designed with optimized drainage patterns and lighter yet stronger materials to reduce energy consumption. In wastewater and mining industries, automated plate-shifting systems and intelligent monitoring solutions are also becoming standard, allowing plants to achieve higher throughput with less labor.

China’s industrial filtration sector continues to invest heavily in R&D to develop next-generation filter plates that meet global environmental and efficiency standards. These improvements not only enhance operational reliability but also align with global efforts to reduce waste and conserve resources.

Conclusion

Across wastewater treatment and mining, the Filter Plate remains the core element that defines the success of the filtration process. Its design, material, and structural quality determine efficiency, maintenance costs, and long-term performance.

As a China manufacturer offering bulk supply of high-performance filter plates, we are committed to supporting industrial partners worldwide with reliable, cost-effective, and sustainable filtration solutions. Whether for municipal wastewater, mineral processing, or chemical production, choosing the right filter plate is key to cleaner processes and higher productivity.

References

GB/T 7714:Teutscher D, Weber-Carstanjen T, Simonis S, et al. Predicting Filter Medium Performances in Chamber Filter Presses with Digital Twins Using Neural Network Technologies[J]. Applied Sciences, 2025, 15(9): 4933.

MLA:Teutscher, Dennis, et al. "Predicting Filter Medium Performances in Chamber Filter Presses with Digital Twins Using Neural Network Technologies." Applied Sciences 15.9 (2025): 4933.

APA:Teutscher, D., Weber-Carstanjen, T., Simonis, S., & Krause, M. J. (2025). Predicting Filter Medium Performances in Chamber Filter Presses with Digital Twins Using Neural Network Technologies. Applied Sciences, 15(9), 4933.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province