NewsDetails

Automatic Filter Press: Working Principle, AdvantagesInternational Technical References

author:Shuangcheng time:2025-07-09 12:12:11 Click:108

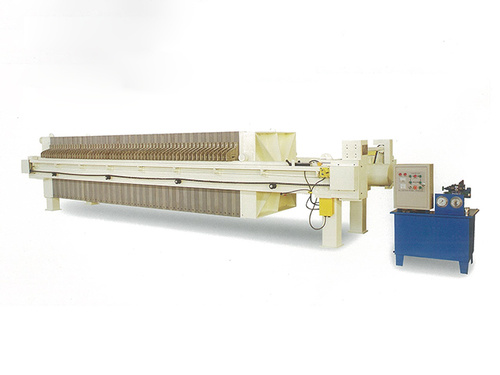

In the field of industrial filtration, the automatic filter press stands out for its efficiency, intelligence, and reliability. It has become an indispensable solution across industries such as chemicals, pharmaceuticals, food processing, and environmental wastewater treatment. This article provides a comprehensive overview of its working principle, key advantages, and insights into global technical research and development trends.

1. Working Principle of an Automatic Filter Press

The automatic filter press operates on the principle of pressure-driven solid-liquid separation. Its core components include filter plates, filter cloths, a hydraulic system, and an intelligent control unit. The typical process includes:

·Plate Closing: A hydraulic system drives the cylinder to press the filter plates together, forming individual filtration chambers. The filter plates, often made of reinforced polypropylene, are corrosion-resistant and structurally robust. Their conical point design promotes even fluid distribution and enhances filtration efficiency.

·FeedingFiltration: The feed pump delivers slurry into the chambers. Under pressure, the liquid passes through the filter cloth, while solids are retained to form a filter cake. Filter cloth aperture sizes are selected according to material characteristics to optimize filtration accuracy.

·Pressure HoldingDewatering: Once the filter cake reaches a certain thickness, pressure is maintained to further dewater the cake and reduce moisture content. Some models include membrane squeezing, using compressed air or water to apply secondary pressure, significantly improving dewatering efficiency.

·DischargeCleaning: After filtration, the system releases the filter plates, and the filter cakes drop off automatically due to gravity. An automatic cleaning system then flushes the filter cloths using high-pressure water to remove any residue, ensuring consistent filtration quality for the next cycle. All steps can be controlled via a PLC system for full automation.

2. Key Advantages of the Automatic Filter Press

·High EfficiencyEnergy Saving

Advanced hydraulic and control systems ensure fast pressing and stable pressure holding, drastically shortening the filtration cycle. Optimized filter plate structures reduce resistance and improve throughput while lowering energy consumption. In practical use, many industries report a significant increase in filtration speed and a reduction in operating costs.

·Smart Automation

Equipped with PLC control and HMI (human-machine interface), operators can easily set parameters, monitor system status, and even control the machine remotely. Features such as auto pressure compensation and fault alarms ensure stable and safe operation throughout the process.

·Easy Maintenance

The modular design allows for easy filter plate removal and cloth replacement. The automatic cloth washing system reduces labor intensity and extends cloth life. Some models also include drip trays or liquid collection systems to prevent leakage and maintain a clean work environment.

·High Adaptability

The machine can be configured with different materials for filter plates and cloths to suit various types of corrosive, viscous, or high-temperature media. For example, specially designed plates with cake release mechanisms can improve discharge efficiency in applications such as metallurgical wastewater treatment.

3. Academic ResearchTechnical References

The development of automatic filter presses is closely supported by international research and engineering innovation. Several open-access studies and technical reports provide insights into the global evolution of filtration technology. Representative topics include:

·Optimization of Solid-Liquid Separation

Studies highlight how filter plate geometry and cloth material influence fluid dynamics and dewatering performance. Experimental and simulation results validate that structural improvements can significantly enhance filtration efficiency.

·Smart MonitoringControl

Integration of PLC systems with sensor feedback mechanisms enables real-time pressure adjustment and process automation, contributing to increased reliability and safety.

·Hydraulic System Innovations

Modern research focuses on designing hydraulic units that are energy-efficient and quiet while providing precise pressure control, ensuring prolonged equipment life.

·Materials for Harsh Conditions

Advanced materials with anti-stick, high-temperature, and corrosion-resistant properties are being developed to expand the applicability of filter presses in demanding industrial environments such as chemical processing and environmental remediation.

The above references are based on public international research literature and technical reports. They are provided to highlight general industry trends and innovations rather than promote specific products or brands.

4. Conclusion

As a key piece of equipment in modern industrial filtration, the automatic filter press offers unmatched performance in terms of efficiency, intelligence, and adaptability. With the integration of cutting-edge technology and automated control systems, filter presses are evolving toward greater sustainability and productivity.

We are committed to delivering high-performance, durable, and intelligent filter press solutions tailored to your specific needs. If you’re looking for reliable equipment or expert technical support, feel free to contact us. We’re ready to provide customized solutions and professional services to enhance your production capabilities.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province