NewsDetails

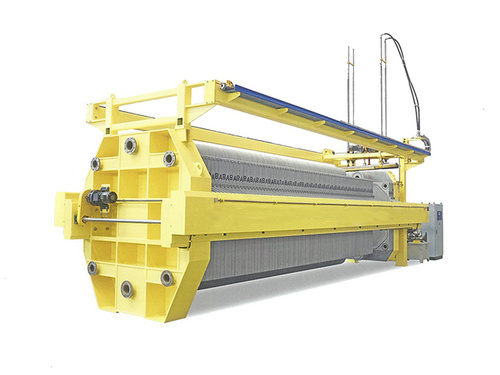

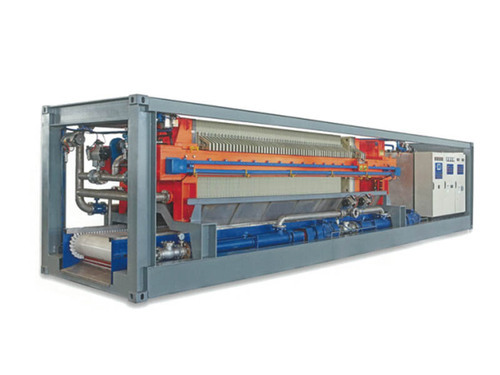

Industrial Automatic Filter Presses: Key Applications in Mining, Chemical, and Wastewater Treatment Industries

author:Shuangcheng time:2025-07-16 02:51:36 Click:172

As industrial technologies continue to advance, solid-liquid separation plays an increasingly vital role in modern production processes. Among various separation solutions, the industrial automatic filter press has become a key technology due to its high degree of automation, efficient performance, and reliable operation. Its extensive adoption across mining, chemical processing, and wastewater treatment sectors has proven essential in supporting production efficiency and environmental compliance.

1. Applications in the Mining Sector

Tailings Dewatering

Mining activities generate large volumes of tailings containing high moisture content. If discharged untreated, these tailings can occupy significant land resources and cause environmental risks. Automatic filter presses efficiently reduce the moisture content of tailings, transforming them into drier filter cakes that are easier to store, transport, or repurpose (e.g., for construction materials). This also minimizes the space and cost required for tailings pond construction.

For instance, in a gold mine application, the moisture content of tailings was reduced from over 70% to around 20% using an automatic filter press—reducing the total tailings volume by approximately 60% and improving overall waste management.

Concentrate Filtration

In ore beneficiation, where grinding and flotation are used to extract valuable metals, automatic filter presses assist in dewatering mineral slurries. By precisely controlling filtration pressure and cycle time, these systems deliver high-purity mineral concentrates and improve metal recovery rates—helping enhance production yields and cost-efficiency.

2. Efficiency in Chemical Processing

Separation of Reaction Products

Many chemical production processes (such as dyes, resins, and agrochemicals) involve solid-liquid mixtures. Automatic filter presses play a critical role in separating precipitated solids from liquids, ensuring high product purity. Their automated operation reduces the risk of human error and enhances batch consistency and production stability.

Chemical Wastewater Pretreatment

Chemical plants often generate wastewater containing suspended solids, heavy metals, or organic compounds. An automatic filter press can act as a primary treatment step, removing solids before further purification. This reduces COD and turbidity, facilitating more effective secondary or tertiary treatment stages and supporting discharge or reuse compliance.

3. Municipal and Industrial Wastewater Treatment

Municipal Sludge Dewatering

The rising volume of urban wastewater has made sludge management a critical challenge. Automatic filter presses are widely used in municipal wastewater treatment plants for sludge dewatering. They reduce sludge moisture content to below 60–80%, significantly shrinking sludge volume and making it easier and more cost-effective to transport, incinerate, or landfill.

Industrial Effluent Management

Industrial wastewater often contains complex pollutants. By selecting appropriate filter cloths and operational parameters, automatic filter presses can effectively separate suspended solids from process water. Industries such as pharmaceuticals, food processing, and electronics benefit from this technology to meet strict discharge standards or enable water recycling—ultimately lowering operational water costs.

Core Advantages of Industrial Automatic Filter Presses

·Fully Automated Operation: Covers feeding, filtration, squeezing, discharge, and cloth washing with minimal manual intervention.

·High Throughput Capacity: Capable of processing large volumes, making it suitable for both batch and continuous operations.

·Excellent Filtration Results: Produces low-moisture filter cakes and clear filtrate through precision control of pressure, time, and filter media.

·Stable and Reliable Performance: Engineered with robust mechanical and control systems for long-term, uninterrupted operation.

Conclusion

The industrial automatic filter press has become a preferred solid-liquid separation solution across mining, chemical, and wastewater sectors. Its automation, efficiency, and adaptability make it an ideal choice for companies seeking to optimize processes and reduce environmental impact. If your business is looking for high-performance separation equipment, our automatic filter press systems are engineered to meet your needs with tailored solutions and responsive technical support.

Recommended International References

·Wills’ Mineral Processing Technology

A comprehensive guide to mineral separation technologies, including key design principles for filtration and tailings management.

·Chemical Engineering and Processing: Process Intensification

Peer-reviewed studies on process optimization in chemical manufacturing, highlighting the role of automatic filter presses in enhancing separation efficiency.

·Water Research Journal

A leading journal in water treatment science, including research on sludge dewatering and wastewater filtration technologies.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province