NewsDetails

Automatic Filter Press Maintenance Guide: Tips to Extend Equipment Lifespan

author:Shuangcheng time:2025-07-19 04:16:58 Click:86

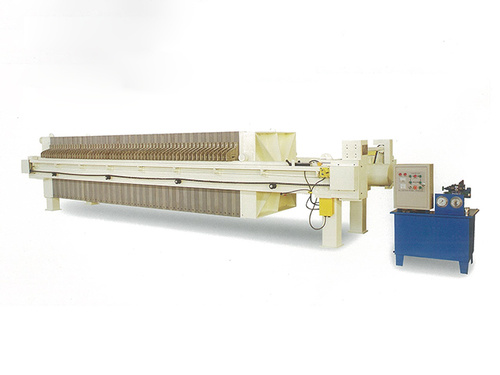

In modern industrial operations, the Automatic Filter Press has become an essential piece of equipment for solid-liquid separation, offering efficient and reliable performance across industries like wastewater treatment, mining, pharmaceuticals, and food processing. However, like all precision machinery, the filter press demands proper care to function optimally over time.

In this comprehensive maintenance guide, we’ll outline best practices and expert insights that help extend the lifespan of your automatic filter press while ensuring consistent performance and reduced operating costs.

1. Understand the Key Components of an Automatic Filter Press

Before diving into maintenance tips, it’s important to understand the major components of your automatic filter press, as each has different maintenance needs:

·Filter plates – Responsible for separating solids from liquids.

·Hydraulic system – Applies pressure to keep plates sealed during the filtration cycle.

·Filter cloth – Acts as the filtration medium; its cleanliness affects performance.

·Control system – Manages the press’s automatic operations.

·Plate shifting and cake discharge systems – Facilitate automated plate movement and unloading.

Regular inspection of these areas ensures you catch potential issues early.

2. Establish a Routine Inspection Schedule

One of the most effective ways to prolong the life of your automatic filter press is to develop a consistent inspection routine. Here’s a basic checklist to follow weekly or monthly, depending on your operation’s intensity:

·Check hydraulic fluid levels and look for leaks

·Inspect filter cloths for clogging, fraying, or excessive wear

·Test sensors and control systems for responsiveness

·Examine filter plates for cracks, warping, or buildup

·Ensure plate shifting mechanism operates smoothly without jamming

Document your inspections to track recurring issues or wear trends.

3. Prioritize Filter Cloth Maintenance

The filter cloth is one of the most critical yet often overlooked components in any automatic filter press. A dirty or damaged cloth can severely impact efficiency, leading to higher moisture content in the filter cake or longer filtration cycles.

Maintenance Tips:

·Wash filter cloths regularly using warm water or approved detergents

·Avoid high-pressure hoses that can damage cloth fibers

·Replace cloths when pores become blocked or when they lose filtration efficiency

·Store spare cloths in a clean, dry environment

Investing in cloth care translates directly to improved separation quality and energy efficiency.

4. Monitor and Maintain Hydraulic Systems

The hydraulic system powers the press and ensures that plates are tightly closed during filtration. Over time, hydraulic fluids can degrade, and seals can weaken, leading to loss of pressure and inefficient operation.

Recommendations:

·Change hydraulic oil every 6–12 months or as per the manufacturer’s guidelines

·Check oil filters and reservoirs for debris or contamination

·Inspect and replace worn seals and hoses before failures occur

·Maintain proper oil temperature during operation

A stable hydraulic system helps reduce cycle times and energy consumption.

5. Calibrate and Clean Sensors and Controls

Automation brings many benefits, but only if sensors and control units are well maintained. Faulty or unresponsive sensors can lead to cycle delays, incorrect cake release, or system shutdowns.

Best Practices:

·Clean sensors regularly to remove dust, residue, or oil

·Update software/firmware if your system is programmable

·Test emergency stop functions and remote-control features

·Schedule annual professional calibrations if available

Modern automatic filter presses rely heavily on electronics, making this an essential part of your maintenance routine.

6. Ensure Proper Plate Alignment and Handling

Misaligned filter plates can cause leaks, damage the press, or wear down cloths prematurely. This is particularly relevant in automatic models where plates are moved by mechanical shifters.

Tips:

·Inspect plate alignment weekly and after any mechanical jamming

·Clean plate edges and sealing surfaces to prevent buildup

·Lubricate guide rails and shifters regularly for smooth movement

·Train operators to load/unload plates with care during manual interventions

Avoiding misalignment reduces wear and improves operational safety.

7. Keep the Entire Press Clean and Dry

General cleanliness plays a bigger role than many operators expect. Spilled slurry, leaking water, or dusty environments can cause rust, component failure, and contamination of your final product.

What to Do:

·Wipe down exposed metal parts and moving elements daily

·Ensure proper drainage systems are installed to divert leaks

·Protect electrical components from water or humidity

·Conduct a deep clean every month during scheduled downtime

Cleanliness is not just cosmetic—it protects your machine from premature degradation.

8. Replace Worn or Aging Components Proactively

Waiting for parts to fail is a costly strategy. Instead, follow preventive maintenance schedules and replace components like filter cloths, seals, and hoses before they fail.

Proactive Replacements Should Include:

·Filter plates (every few years depending on use)

·Cloths (based on cycles and wash frequency)

·Hydraulic seals and filters

·Control fuses, relay switches, and sensors

Keeping spare parts in stock ensures minimal downtime during emergencies.

Conclusion: Your Automatic Filter Press Deserves Attention

A well-maintained Automatic Filter Press delivers superior performance, consistent results, and lower long-term costs. By following these best practices—from filter cloth care to hydraulic upkeep—you can extend your machine’s lifespan, reduce downtime, and ensure seamless operation across production cycles.

Whether youre processing slurry in wastewater treatment or separating solids in food manufacturing, proper maintenance will keep your automatic filter press working at peak performance for years to come.

References

·Zhao, L. (2022). Maintenance Planning for Industrial Filter Presses. Journal of Process Engineering.

·Smith, A.Taylor, J. (2021). Hydraulic Systems in Modern Filtration Equipment. Industrial Mechanics Review.

·Kim, H. (2023). Predictive Maintenance Strategies for Automatic Filter Presses. Engineering Maintenance Quarterly.

·Chen, D. (2020). Solid-Liquid Separation Technologies and Best Practices. Chemical Plant Management.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province