NewsDetails

Chamber Filter Press | Features, Benefits, and Industrial Applications

author:Shuangcheng time:2025-09-05 18:27:43 Click:141

Why Chamber Filter Press Matters

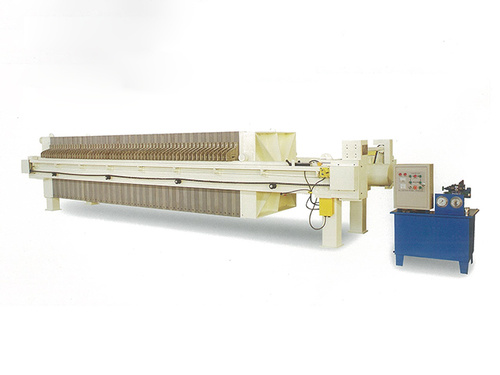

The Chamber Filter Press is a critical equipment in modern solid-liquid separation processes, widely used in industries such as mining, chemical processing, wastewater treatment, and food production. Its robust design, high filtration efficiency, and ease of operation make it a reliable choice for companies seeking consistent and high-quality output.

For businesses sourcing from China filter press suppliers or Chinese filter press manufacturers, understanding the features and benefits of a chamber filter press ensures a smart investment that optimizes both operational efficiency and cost-effectiveness.

What is a Chamber Filter Press and How Does it Work?

A Chamber Filter Press consists of a series of recessed filter plates lined with filter cloth, forming chambers where slurry is pumped under pressure. The liquid passes through the cloth while solids accumulate as a filter cake. Its working principle combines mechanical pressure, filtration cloth efficiency, and hydraulic systems to achieve high-quality separation.

Key components include:

·Filter Plates: Recessed plates create chambers for slurry storage and dewatering.

·Filter Cloth: Acts as the primary barrier to separate solids from liquid.

·Hydraulic System: Provides uniform pressure across all chambers for effective filtration.

·Frame and Support: Durable construction ensures long-term operational stability.

This design ensures high dryness of filter cakes, minimal slurry loss, and reduced maintenance requirements, making it preferable to other filtration systems in many industrial applications.

Key Features of a Chamber Filter Press

1.High Filtration Efficiency: Produces dry, compact filter cakes, reducing waste disposal costs.

2.Customizable Chamber Size: Plates and chamber dimensions can be adapted to specific production volumes.

3.Durable Construction: Made from corrosion-resistant materials such as polypropylene, stainless steel, or coated carbon steel.

4.Semi-Automatic or Fully Automatic Operation: Reduces labor intensity and increases operational safety.

5.Low Energy Consumption: Hydraulic systems are optimized for energy efficiency while maintaining high performance.

Advantages of Chamber Filter Press Over Other Systems

·Better Cake Dryness: Chamber design achieves lower moisture content compared to belt or plate-and-frame filters.

·Compact Footprint: Saves floor space in industrial plants.

·Versatility: Suitable for a wide range of slurries, including abrasive, viscous, or chemically aggressive materials.

·Cost-Effectiveness: Lower maintenance and operating costs make it ideal for SMEs and large-scale industries alike.

The combination of these advantages is why many industries prefer sourcing Chamber Filter Press units from China filter press suppliers, where technology and affordability meet international standards.

Industrial Applications of Chamber Filter Press

1.Mining and Metallurgy: Tailings dewatering, metal recovery, and mineral concentrate processing.

2.Chemical Industry: Processing of chemicals, pigments, and pharmaceutical intermediates.

3.Food and Beverage: Clarification of juices, sugar refining, and starch processing.

4.Wastewater Treatment: Sludge dewatering in municipal and industrial wastewater plants.

5.Environmental Protection: Reduction of industrial effluent volume and improved recycling efficiency.

By choosing Chinese filter press manufacturers, industries can access reliable systems tailored to these specific applications, ensuring both performance and compliance with global standards.

How to Choose the Right Chamber Filter Press

When selecting a Chamber Filter Press, consider the following:

·Filtration Capacity: Match the press to your production volume.

·Plate Material: Choose polypropylene, stainless steel, or other resistant materials based on slurry type.

·Automation Level: Decide between semi-automatic or fully automated presses according to workforce and operational needs.

·Supplier Reliability: Ensure the China filter press supplier provides technical support, spare parts, and after-sales service.

·Compliance & Certification: ISO and CE certification guarantee product quality and safety standards.

Conclusion: Invest Wisely in Chamber Filter Press

The Chamber Filter Press remains a cornerstone of modern solid-liquid separation processes, combining efficiency, reliability, and adaptability. By leveraging the latest features, selecting the right material, and sourcing from trusted China filter press suppliers or Chinese filter press manufacturers, businesses can optimize productivity, reduce operating costs, and secure a long-term solution for industrial filtration.

Choosing the right Chamber Filter Press today ensures smoother operations, higher throughput, and consistent product quality tomorrow.

References

GB/T 7714:Yılmaz G. Sludge Dewatering by Chamber Filter Presses[M]//Handbook of Water and Used Water Purification. Springer, Cham, 2021: 1-8.

MLA:Yılmaz, Gülşen. "Sludge Dewatering by Chamber Filter Presses." Handbook of Water and Used Water Purification. Springer, Cham, 2021. 1-8.

APA:Yılmaz, G. (2021). Sludge Dewatering by Chamber Filter Presses. In Handbook of Water and Used Water Purification (pp. 1-8). Springer, Cham.

Recommended Products

Recommended Products

Contact us

Contact us

—— Contact:Manager

—— Tel:+86 16632826789

—— Email:sales@hbscfilterpress.com

—— Url:https://www.hbscfilterpress.com

—— Address:West Zone of Economic Development Zone, Fucheng County, Hengshui City, Hebei Province